CNC Automation for Milling Machines

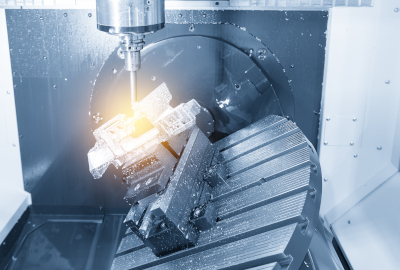

Machining Center + Automation = Rewarding Investment

One automated universal machining center can produce as much as three non-automated ones. Fastems supplies pallet automation solutions ranging from single machine tool production cells to extendable linear pallet system with a dozen of machines.

With Fastems, you can also integrate tool automation, turning machine automation and a wide variety of other machinery and processes into the same system. See the case video as an example of a highly-automated milling manufacturing!

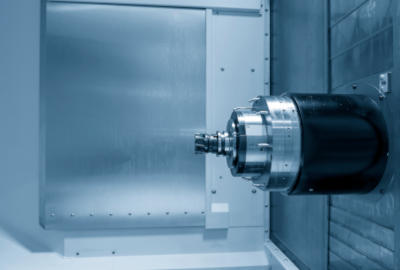

What Kind of Milling Machines Do We Automate?

We have solutions for all kinds of milling machines: 3-axis, 4-axis, 5-axis, mill-turns and so on. Automatic pallet changers (APCs) typically used in 4-axis horizontal machines help with quick pallet change and easy table reach but the non-APC machines like 5-axis trunnions or turn-mills are just as suitable for flexible automation.

The pallet sizes vary from 300 to 1600+ mm, and we handle traditional as well as zero point pallets that require workpiece centering. Pallets are moved with industrial robots in the lighter end and with stacker cranes in heavier payload solutions. AGV based systems are also entering the shop floors.

Download our guide to learn more about automating milling machines

Automation Benefits

Why Should You Consider Automating Your Milling Machines?

Flexible automation does not only allow for higher production capacity – it helps businesses to scale when demand fluctuates, save time from repetitive work such as production setups and manual transfers, and reduce money tied in WIP and inventories. And much more.

Higher revenue and profits with less tied capital

Improved financial results are of course driven by development in operations such as higher utilization of resources, more throughput, higher quality or more proactive production planning. The effect in short: the production achieves higher volumes and profits and operates with less money (less stocks and WIP).

Less idling, more capacity, higher quality and easier production planning

Automation transforms the daily operations making them much more productive, efficient and stable. By automating and with the help of intelligent planning and resource management features of MMS control, the production can achieve high flow and resource efficiencies.

Happier people, customers and planet

Automation helps fighting the challenges of finding and keeping skilled labor and being able to deliver quality on time. By increasing resource efficiency and making jobs more meaningful, safe and accessible it also supports in reaching sustainability targets.

Solution Finder

Find just the right solution for your 3 to 5 axis milling machines or turn-mills with our easy solution finder. If you don’t find a solution for your machine with this tool just contact us directly – we are an open integrator and can automate almost any machine tool!

After finding your solution, download our guide to learn more on how to automate milling machines

Filter by

Machine tool or process type

Filter by

Qty of machines

"*" indicates required fields