Material Bank for CNC Manufacturers

Guides

Ultimate Guide for Intelligent Automation

Guide for producing small batches economically by optimizing production planning, start setup, cutting tool management, transfers and loading between process phases, quality and traceability, and the machine tools.

DownloadAerospace Automation Guide

High-Mix-Low-Volume CNC Manufacturing Guide for Aerospace and Defense

DownloadAutomation Guide for Pump, Valve, Cylinder and other Fluid Manufacturers

High-Mix-Low-Volume CNC Automation Guide for Pump, Valve, Cylinder and other Fluid Manufacturers

DownloadWebinar recordings

The Best High-Mix Automation Practices for Turning Machine Tools

Learn the best CNC automation practices for running high mix with multi-tasking lathes and turn-mill machining centers! In this demonstration our experienced robotics specialist, Teemu-Pekka Ahonen, shows the basics of flexible automation using Fastems’ automation control software MMS. How to ramp up automated high-mix production? How to repeat a previously machined part with minimum effort? How to introduce brand new work pieces easily

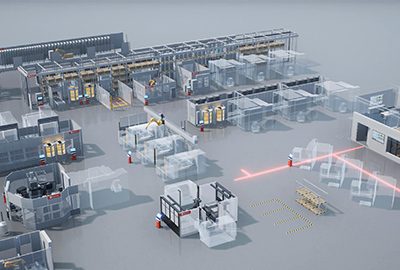

Automate 4 and 5 Axis CNCs for Efficient High Mix Manufacturing Webinar

Compared to single-machine automation, flexible manufacturing systems (FMS) offer lower unit cost, shorter lead times and more consistent quality in high mix production. What FMS actually is about – why to favor multi-machine automation and how to manage production resources (tools, NC programs, raw materials, work holding) around machining? These are all questions that we answer in this webinar.

Watch the recordingAerospace & Defense CNC Automation webinar

After studying over 5,000 successful automation implementations for high-mix manufacturers, we are excited to share essential shop floor practices and automation insights tailored for aerospace and defense businesses. Discover how the right automation strategies can help you deliver top-quality parts and keep lead times short without having a huge inventory – helping you win more contracts and meet demanding industry standards.

Watch the RecordingNC Program Management with Fastems CNC Automation

One of the most loved features in Manufacturing Management Software is the NC Program Management which saves significant time and effort from the NC programmers. No matter if you are a Fastems user already or just considering to automate your CNC machine(s), this webinar offers insightful views on how CNC automation can help in streamlining the NC program management.

Watch the recordingMMS for Work Cell Operation

We all know how the intelligent Fastems Manufacturing Management Software is when it comes to planning, running, and monitoring your automated production in the shop floor. But, have you been wondering about how to manage your non-automated work cells without using papers and complicated Excel files? If the answer is yes, this is THE EVENT for you to participate!

In this webinar, we are introducing Work Cell Operations (WCO) – an additional MMS software that allows you to plan and control stand-alone machine tools and manually operated work stations, while at the same time utilizing the unique features of the traditional MMS.

Watch the RecordingAutomating Existing Machine Tools – Do I always need to buy new ones?

Automating existing machine tools is no myth or scifi dream but a practice that Fastems has been doing for years with clear bottom line: there are plenty of situations where automating your current machine tools pays off and there are ways to navigate through the necessary technical landscape around machine tool interfacing, table or chuck access and safety.

Watch the recordingThe spindle utilization with Fastems FMS can be over 90% – even in a mixed manufacturing environment with hundreds of different components and new ones constantly introduced. What is the secret? Learn four key bottlenecks that are preventing you from reaching full potential, as well as strategies to start optimizing your production for higher profits.

Watch the recordingPodcasts

The Top Five Automation Myths

In this podcast, we sum up the five most typical misconceptions we face, breaking them down to understandable pieces and explaining how we’ve busted them.

ListenThe Daily Life (or Hell) of a Production Manager

This podcast discusses the daily difficulties production managers face and how they can be solved.

ListenTool Management – What is it, why is it relevant and how to improve?

Good tool management is a vital part of an efficiently working shop floor. But what does ‘good’ really mean?

ListenBlog Posts

Six Steps How to Make a Successful FMS Ramp-up

When putting a new automation system to use, the same principle as with a laptop, mobile phone or other smart device applies: the better prepared you are, the faster you can reach maximum benefits.

Read MoreCan Your Pallet Pool Do This? Six Differences Between a Pallet Pool and Flexible Automation

A pallet pool is an easy-to-buy, easy-to-implement automation solution for machine tools. It increases the lights-out manufacturing periods and machine tool utilization up to 65% – no wonder it’s such a popular option. That said, before investing in automation, it’s a good idea to evaluate not only the needs of today, but also the needs of tomorrow.

Read MoreDo You Know The (True) Utilization of Your Machine Tools?

Even today, it’s common for machine tool spindles in job shops to have utilization rates of around only 20 percent. What’s worse is that most of these businesses are operating under the assumption that their rates are much higher: somewhere between 60 to even 70 percent.

Read MoreIf you’d rather just talk to a Fastems representative, we’d love to hear from you!

Give us a call or send an email.

"*" indicates required fields

)

)

)

)

)

)

)

)

)

)

)

)

)