RFC –

Robotic Finishing Cell

Manual, machine or rather flexible deburring with a robot?

The Robotic Finishing Cell (RFC) is a high-performance automation solution for the finishing/deburring of different workpieces that can be flexibly adapted to your individual requirements.

And the choice is yours:

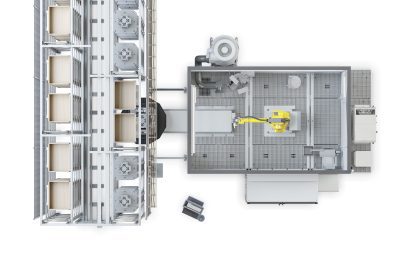

The RFC is designed both as part of a flexible manufacturing system (FMS) from Fastems and for stand-alone operations. The RFC is based on standard modules, which means that the robot cell is optimally prepared for your future production. For you, this means short delivery times and rapid commissioning on site, meaning that the RFC is ready for immediate use.

RFC integrates in an FMS

With integration into an FMS from Fastems, RFC achieves the highest level of productivity, as finishing/deburring is seamlessly integrated into the overall automation as a further value-adding process.

Advantages:

- Simple integration into an FMS from Fastems

- Deburring is an integral part of overall automation

- Long unmanned production hours despite different part types

- Large selection of pneumatic and electric tools

- Production capacity freed up by robot-assisted deburring

- Predictive planning, forecasting and seamless monitoring thanks to the MMS as a standardized control system for machine tools and the RFC

- Greater transparency and safety: checking of tool status, tool life and availability in the RFC via the MMS

RFC as a stand-alone solution

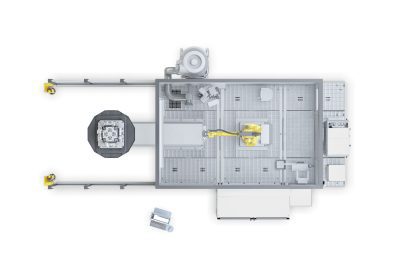

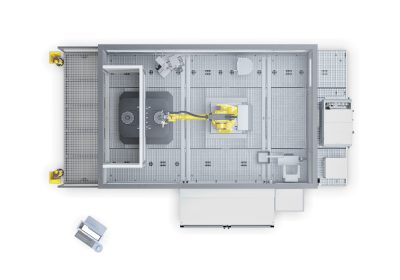

With the RFC as a stand-alone solution, you take a decisive step forward, because the robot cell offers a whole range of options, both in the choice of loading and unloading stations and in terms of flexible configuration.

Advantages:

- Shorter non-productive times thanks to loading and unloading of the cell during machining time

- Significant time savings thanks to unmanned, automated deburring

- High flexibility and productivity thanks to individually loadable tool magazine

- Large selection of pneumatic and electric tools

- Production capacity freed up by robot-assisted deburring

- Simple planning and seamless monitoring thanks to intuitive cell control with the MMS

- Greater transparency and safety: check tool status, tool life and availability in the RFC via the MMS

PERFECT RESULTS EVERY TIME

Large Selection of

Tools and Accessories

The results of robot-assisted deburring depend to a large extent on the choice of suitable tools – and there is plenty to choose from.

In addition to the RFC as a highly flexible system platform, there is therefore a wide range of tools and accessories from a single source:

- Electric and pneumatic tools,

- Roll media that can be used with FlapGrinder technology, e.g:

- Sandpaper or sanding belts,

- Electric belt sanders with belt magazines,

- Random orbital sanders for surface finishing,

grinding wheel magazines with automatic wheel change,

etc.

With a tool magazine equipped according to your individual requirements, you save an enormous amount of time and can start processing parts immediately.

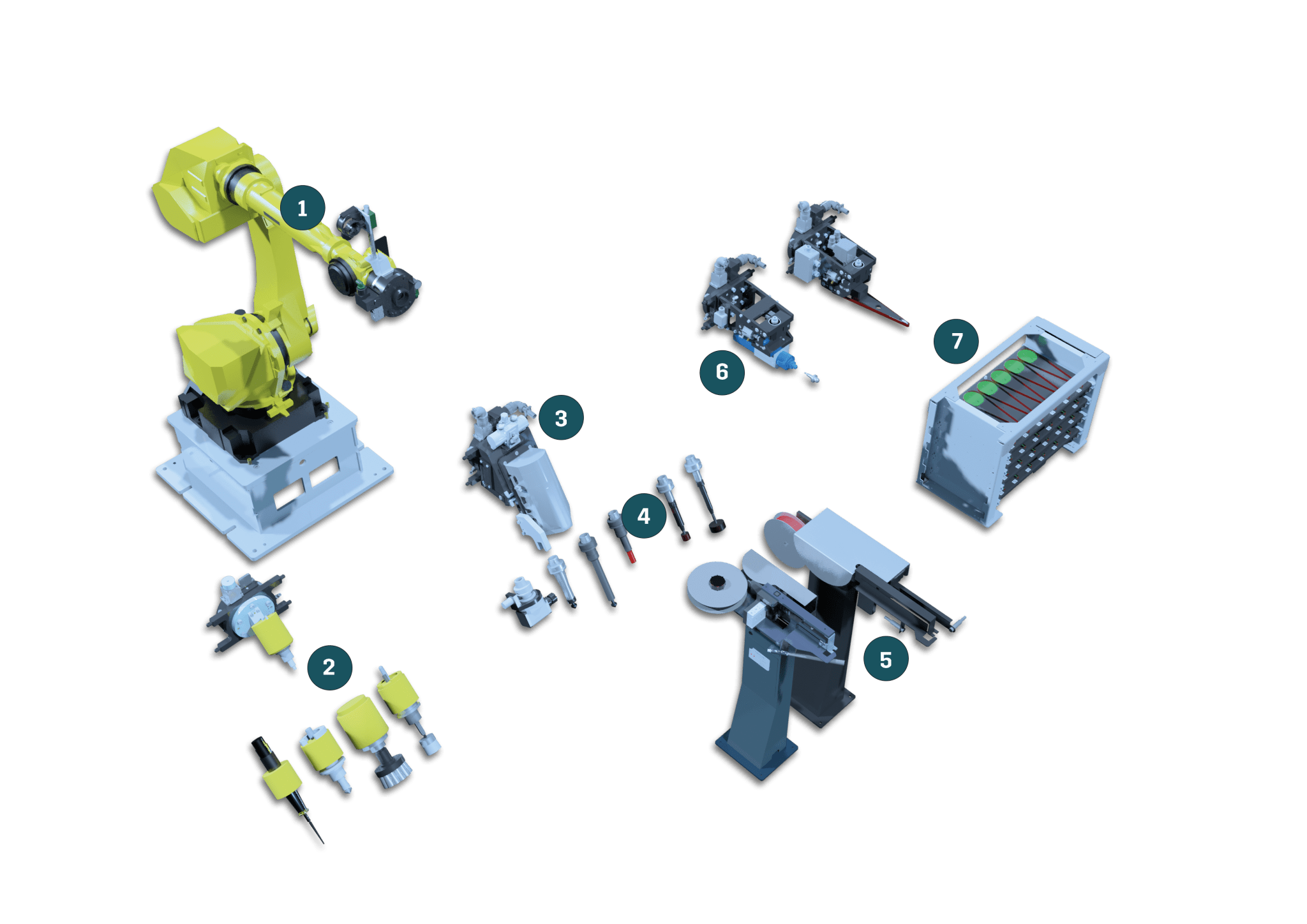

| 1 | Robots 2 | Pneumatic spindles 3 | Spindles with high torque 4 | Tool holders with a large selection of tool attachments |

5 | FlapGrinder system 6 | High-speed electrospindle with interchangeable tool holders 7 | Servo belt grinder with magazine |

“PART-TO-TOOL” OR “TOOL-TO-PART”?

Workpiece or tool-guided deburring?

Two processes are available for robot-assisted finishing: workpiece-guided (part-to-tool) and tool-guided (tool-to-part) deburring. With the part-to-tool principle, the robot handles the workpieces and guides them to the deburring tools. This process can only work with a fixed number of spindles and therefore a limited selection of tools.

In contrast, the RFC was developed for the tool-to-part principle for good reasons. This solution offers an extremely high degree of flexibility both in terms of the mix of parts (size, weight and geometry of the workpieces) and the number of different tools provided for this purpose.

Advantages

of tool-guided deburring:

- Perfect for a wide range of parts, as the number of tools is not limited.

- Wide product range, as the option for a larger selection of tools is available right from the start.

- Easier deburring, even of large and heavy workpieces, as the robot guides the tool and not the workpiece.

- Greater flexibility when introducing new workpieces, as a large number of tools can be accessed.

- Greater security for the future thanks to a flexibly scalable tool inventory.

- Greater cost-effectiveness, as investments are limited to the tool inventory, which can also be expanded as required.

More safety:

Program deburring processes offline

& test them virtually

When introducing new parts into production, programming for deburring can be time-consuming, whereby the robot cell is not in operation for part of this time and therefore no workpieces are processed.

Program, simulate and test the deburring processes offline before the workpieces even exist.

More productivity:

Customized

feasibility analyses

If very specific parts need to be deburred, we carry out feasibility analyses in advance using customer-specific sample parts to check which tools, programs, robot travel paths, etc. are most effective. A fully equipped RFC is available in our development center for such analyses as well as process and tool development.

EASY USER GUIDANCE

MMS –

Plan ahead, monitor seamlessly

The Manufacturing Management Software (MMS) from Fastems is one of the most powerful solutions for

planning, execution and monitoring of automated production.

The intuitive MMS also offers all the functions required for flexible finishing and deburring

of a large number of different part types.

MMS for the RFC as

a component of an FMS

Thanks to the MMS, an RFC can be seamlessly integrated into automated overall production planning as part of an FMS.

THE ADVANTAGES

- Clear management of different orders

- Uniform control for the machine tools and the RFC in an FMS

- Complete management of RFC tool master data

- Transparent monitoring of tool status, operating time and tool life

- Automatic and continuous checking of tool availability

MMS for the RFC as a

stand-alone solution

Thanks to the MMS for an RFC as a stand-alone solution, the planning and monitoring of finishing and deburring processes is much easier.

THE ADVANTAGES

- Clear management of different orders

- Simple processing of different parts with corresponding tools thanks to work sequences

- Complete management of RFC tool master data

- Transparent monitoring of tool status, duration of use and tool life

- Automatic and continuous checking of tool availability

FACTS

Technical Data

RFC – Integrated with FMS |

RFC – Stand-Alone |

RFC – Stand-Alone |

|

| RSS / RSM-Station | RSM-Station | RSR / RSRT-Station | |

|

|

|

|

| Max. Diameter | 1.650 mm | 1.650 mm | 500 mm |

| Max. Height | 1.800 mm | 1.800 mm | 1.000 mm |

| Max. Weight (Including Pallets) | RSS-25 | RSM-25: 2.500 kg RSS-60 | RSM-60: 6.000 kg |

RSM-25: 2.500 kg RSM-60: 6.000 kg |

500 kg |

| Tool magazine | Max. 2 Magazines |

Max. 2 Magazines |

Max. 2 Magazines |

| Capacity Tool magazine |

3 x 10 Tool magazines |

3 x 10 Tool magazines |

3 x 10 Tool magazines |

| Belt / Sandpaper

Magazine |

Max. 2 Tool magazines |

Max. 2 Tool magazines |

Max. 2 Tool magazines |

| Capacity

Spindle magazine |

Max. 4 Tool magazines |

Max. 4 Tool magazines |

Max. 4 Tool magazines |

| RSS – Robot Station Stationary RSM – Robot Station Moving |

RSR – Robot Station Rotating RSRT – Robot Station Rotating Tilting |

DOWNLOAD

Guide:

Flexible robot-assisted finishing

Manual, mechanical or flexible deburring with a robot?

This guide provides valuable orientation on this topic, presenting the Robotic Finishing Cell (RFC) as an economical solution for automated deburring. The RFC can be used either as a stand-alone solution or as part of a Flexible Manufacturing System (FMS) from Fastems, with the guide going into more detail on the advantages and disadvantages of both solutions.

"*" indicates required fields

"*" indicates required fields