The history of Fastems

A Pioneer in Manufacturing Technology

Fastems is combination of visionary engineering, a firm dedication to customers, and an ambition to push for the future of manufacturing technology. Our story began in 1901 and the last 120 years signify an ascent from an expert in machining, machine building and special machine tools into a global leader in high-mix manufacturing automation. What remains unchanged is our DNA: the passion for understanding and solving customer challenges with leading engineering and technology. Rather than equipment, Fastems’ purpose is to deliver change and tools for the metalworking manufacturers to build their future with, making the whole industry more competitive and sustainable.

Section quick links:

Summary

Fastems is built on two historical cornerstones. The first one is with Mercantile, a great Finnish trade house with a large industrial machinery import division, including machine tools since the 1920s and robots since the 1980s. The second is the manufacturing, special machine tool and manufacturing technology development unit called Linnavuori Works, established by a distinct Finnish industrial conglomerate, Valmet, in 1942.

Fastems brand was born in 1994 as Valmet decided to establish the special machine tool and automation businesses known as Valmet Factory Automation as an independent company that it then sold to Sisu, a Finnish manufacturer of heavy vehicles and defense equipment. The name Fastems comes from Factory Automation sySTEMS.

Mercantile acquired Fastems in 1995, combining it with its own machine tool and robot business, with a vision to build a global expert in automation, machining, and manufacturing technology. The parent company Mercantile has since been renamed Helvar Merca. Today, Fastems is one of several ‘Cousin Companies’, a portfolio of businesses held by the Aminoff family, with annual revenue exceeding 2 Billion euro, employing over 3500 people.

The founding and expansion of Mercantile, 1901-1940s:

Mercantile was founded in 1901 in Tampere, Finland, by a young businessman Charles Elmgren to import machinery and chemicals from Germany. Due to Elmgren’s illness and early death, the company was raised by his brother-in-law, Walter Greuling, to become one of the largest trade houses in Finland in just a few decades. Walter was the son of local factory director, Max Greuling, who moved from Germany to Finland to drive local industrialization. Machine tool imports have been part of Mercantile’s business since the 1920s along with machinery for the paper industry, generators, turbines, and textile industry. The company also established very significant imports of chemicals and steel.

Early Mercantile advertisement on machine tools in Swedish

Walter Greuling was the sole owner and Chairman of the Board of Mercantile until he died in 1944, leaving the company and his other businesses for his two daughters, both married to the Aminoff family. The family, headed by Walter Greuling’s son-in-law Cecil Aminoff, started to manage the Mercantile business, which continued to grow significantly. The business philosophy of the Aminoff family has always been to develop all its ‘cousin companies’ to be the leaders of their respective fields which include technology, trade, automotive, and real estate businesses.

Walter Greuling raised Mercantile to it’s greatness.

Linnavuori Works as the crucible of manufacturing and machine building technology, 1940s to 1980s:

Fastems’ second cornerstone lies in the establishment of an aircraft engine factory in a village called Linnavuori (‘castle mountain’), about 20 kilometers west of Tampere in 1942. The main purpose of the facility, related to WWII, was to produce aircraft engines but also spare parts and repair work for them. Linnavuori Works was established by Valmet, A Finnish state-owned industrial conglomerate rooted in industrial machinery, metalworking, textiles, and docking businesses. Valmet later became a world leader in pulp, paper and energy industries and is today listed on the Helsinki stock exchange with a market cap of over 4 Billion EUR.

Linnavuori Works in building phase during the 1940s

It all started with machining, tooling, and machine-building technology development.

After WWII, the Linnavuori Works started manufacturing diesel engines and compressors as war reparations, first under Swedish licenses. In the late 1940s, the site also began its own diesel engine production for heavy vehicles and trains. To support engine manufacturing, the facility started to build special machine tools in the 1950s and in the 1960s, these machine tools were already sold outside Valmet, including exports mainly to the Swedish automotive industry. One central innovator driving the development was engineer Esko Kekki. The last special machine tool built by Fastems or its predecessor was delivered in 2004.

Machining cylinder blocks at Linnavuori Works with Valmet’s own special machine tools in the 1950s

Driving the business of special machine tools at the time was the tooling and machining method development unit at Linnavuori Works. A dedicated business unit for special machine tools was established in 1973 with Heikki Aho (M.Sc) as the leader. Linnavuori works became the largest special machine tool manufacturer in the Nordics during the 1970s, animated by the passion for understanding and solving the manufacturing challenges of our customers.

Because Valmet, during the 1970s and 1980s, was supplying a large variety of industrial machinery, the Linnavuori Works became the unit that pushed machining, tooling, machine-building, and later automation technology forward in Finland and globally. The engineers at Linnavuori Works consulted not just units inside the large corporation but were also the national pioneers driving Finnish industrialization in manufacturing and machine building along with its special machine tool sales.

Special machine tool from the 70s build by the Linnavuori Works

Linnavuori Works would organize annual seminars explaining the latest technologies and how to benefit from them and lecture on engineering classes in Finland. The unit also developed a brand amongst Finnish manufacturing professionals, helping to acquire talent from the technical universities for novel applications like control software for CNC machines and automation systems. As an example, Linnavuori Works developed its own CNC control, Multiway-8, in the 1970s capable of controlling eight numerical axis which was, at the time, globally unique.

Supplying flexible manufacturing systems (FMS) started from a need to push manufacturing and machine-building technology forward.

The idea of flexible manufacturing systems (FMS) emerged in the mid-1960s: the concept was to use a numeric controller that guided pallets from/to machine tools without direct human intervention. Furthermore, the system would typically integrate many manufacturing operations and multiple machines into a single unit. The parts manufactured would be of the same family meaning they had dimensional similarities but were not identical, hence the word ‘flexible’. The early developers of the idea were Molins (UK) and Cincinnati Milacron (USA).

Many factors drove Linnavuori Works to utilize and develop automation: the need to adopt new technology and potential productivity increase were obvious. The unit also saw a bigger and longer-lasting business opportunity in automation as the special machine tools were starting to get replaced by standard machine tools in the late 1970s. The last factor was the maturing of key technologies especially around control software, allowing more versatile and independent manufacturing operations without human intervention.

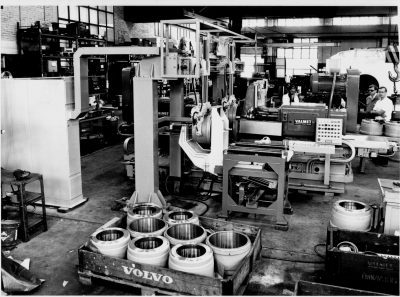

The first portal robotic automation projects by Valmet were delivered, along with special machine tools, in the late 1970s for the Swedish automotive industry, which used to be the main customer segment creating demand for developing manufacturing technology. The parts were primarily for heavy vehicles produced by Volvo or Scania.

A portal loader delivered to Volvo in 1980

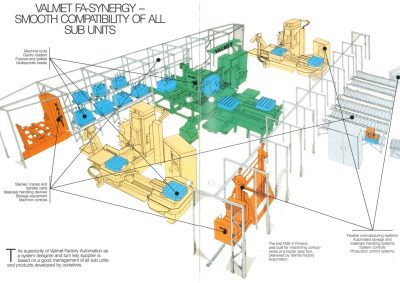

The first flexible manufacturing system (FMS) by Linnavuori Works delivered was in 1982. It was used by Valmet’s own Suolahti facility located nearby, manufacturing parts for tractor gearboxes. The system was decommissioned in 2022, serving over four decades with the help of many modernizations. The system had two Kearney & Trecker horizontal machining centers supplied by Mercantile and one special multi-spindle machine tool by Valmet, featuring automation for changing the spindle heads.

An illustration of the first FMS by Fastems

Right from the first system, Fastems has always been an open integrator that connects the customer-chosen equipment into one automation system. Today we have over 100 brands of machine tools, supportive devices, and software integrated to our systems. The move towards automation was driven by our passion for solving the manufacturing challenges of our customers, as it enabled even more profound and impactful solutions. It has also has kept pushing our engineering capabilities constantly a step further ever since.

To establish automation as a business, in 1984 Valmet Factory Automation unit was born as the special machine tool operations, located in the Linnavuori Works, were merged with another Valmet unit specialized in elevator and automated transfer device manufacturing, located near downtown-Tampere. The ‘FMS group’ was led by Juhani Rantalainen. The core team also included Reijo Tuokko, Pekka Siponen and Jani Granholm, who developed the controls for the first FMS.

The first FMS featured automation for changing multi-spindle heads utilized before the capabilities of single spindle machines matured.

The animating spirit in the late 1970s and early 1980s was of a start-up: the technologies required for machine tool automation weren’t common and were very scattered, markets were at a very early stage, involved people visionary, curious and ambitious, driving the concept of CNC automation forward. The times required a high commitment from the involved people and a backbone to engineer what was promised – and often never done before. During the 1980s Valmet Factory Automation unit delivered hundreds of special machine tools and automation systems mainly to Europe and the Soviet Union. Occasionally the project values were larger than the unit’s annual revenue.

The birth of Fastems, the 1990s:

In the late 1980s Mercantile’s machine tool business unit leaders reckoned that it would need to expand its operations around machine imports to create more customer value. Automation was a natural choice and the company also acquired robot import rights to start delivering robotic automation solutions along with the machine tools. The move towards automation was driven by Mercantile’s machine tool business director Jarmo Hyvönen, who had a background in ABB robotic sales and would later become the first CEO of Fastems, serving between 1995 and 2013.

In the early 1990s Valmet Factory Automation was also involved in a few projects together with Mercantile with clear areas of responsibility: Valmet delivered the automation and Mercantile the machines. This cooperation, dating back to the first FMS delivery, paved the way for a birth of a new company, Fastems.

Fastems was established in 1994 as Valmet decided to separate the Factory Automation business into a dedicated company, which it sold to Sisu, a Finnish manufacturer of trucks for defense and heavy transport. The name comes from Factory Automation SySTEMS. In 1995 Mercantile bought Fastems from Sisu, merging it with its machine tool and robot import business. The central idea of Fastems was to combine the deep know-how around machining and machine building with automation which are the essential parts of its history within Valmet and support that with the high business acumen and leadership of Mercantile.

The 8760 logo was developed Juhani Rantalainen in 1996 as a response to the need to summarize the principal idea of the company visually and conceptually: creating customer value by enabling high machine utilization with the target of ‘24/7’ operations in a high-mix manufacturing context.

Fastems’ first logo version included only the name in blue, but the 8760 ball was soon included.

In 1997 Fastems’ HQ building, including assembly, engineering and support functions was completed in Lahdesjärvi, Tampere. Today, Linnavuori Works is operated by AGCO Corporation, developing and manufacturing world-leading diesel engines with the AGCO Power brand. Fastems supplies automation to the Linnavuori Works also today.

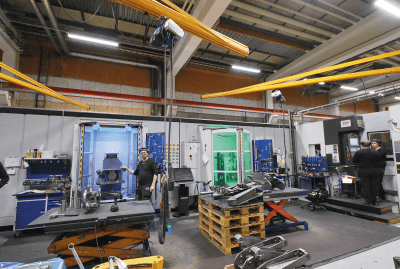

Fastems HQ and main production site was completed in 1997.

Supported by the business leadership of Mercantile and CEO Jarmo Hyvönen, the engineering-focused company started heavy expansion and commercial development, first to Europe and from 1999 onwards to the USA and 2012 to China as well. Previously, Valmet Factory Automation had established units in Germany and Sweden in the late 80s and early 90s. To develop the company and customer value of automation, various kinds of services were introduced in the late 1990s and early 2000s around spare parts, remote support, and modernizations. This trend would continue until today, enabling manufacturers to get the full value out of their automation systems and manufacturing.

The Birth of Intelligent CNC Automation, 2000s–Today:

The last two decades of Fastems history are characterized by development leaps in software, an increasing level of automation, productization and strategic focusing – all contributing to the birth of intelligent CNC automation and thought leadership of Fastems.

The ‘super-brain’ of CNC manufacturing

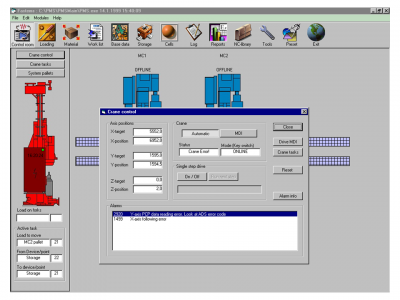

Fastems control software development started in the 1980s with PDP computers that were about the size of a fridge. A crucial milestone was reached in the 1999 EMO Paris exhibition, when Manufacturing Management Software (MMS) version 1.0 was published with the first delivery only a few months later to ABB in Sweden. Read more about the MMS history.

What MMS 1.0 looked like – a shot from January of ’99

Today, MMS is the leading automation control software and a central enabler of efficient and flexible high-mix CNC manufacturing. MMS runs at version 8 and is capable of operation in the pallet handling, part handling and Work Cell Operations domain, which brings MMS benefits to manual operations or stand-alone machines, acting as MES software. For data-driven manufacturing, enabled by situational awareness and related process optimization, Fastems launched a cloud-based tool, Factory Cockpit in 2023. During the same year, Fastems also released free myFastems app, which is used for remote system monitoring, easy diagnostics, spare part orders and more.

The latest MMS version is 8

Productization and automation rate increase

Until the 2000s automation was always custom-built. Today, machine and software interfaces are more standard as well as Fastems’ automation platforms. One milestone in productization was reached in 2001 as Fastems introduced the Flexible Pallet Container (FPC) for 1 to 3 horizontal milling machines with an automatic pallet changer. Today there are over 1000 deliveries of FPC, making it globally one of the most sold systems in its category. The trend in standardization has continued to high-mix turning (RoboCell ONE, RCO) and to larger flexible manufacturing systems (Flexible Pallet System, FPS), finishing (Robotic Finishing Cell, RFC), tool automation (Tool service cell, TSC) and data-driven manufacturing solutions (Factory Cockpit). Today, all Fastems automation systems are built based on platforms, making them more reliable and faster to deliver.

FPC is Fastems’ entry-level automation for 4-axis HMCs – over 1000 delivered systems!

Simultaneously, the level of integrations has also expanded from machine tending to include devices for measuring, marking or washing and robotic automation around finishing, tool management, or part loading to fixtures. The average machine shop today has more sophisticated software systems such as PDM, CAD/CAM, ERP or MES that can all be connected into Fastems automation, increasing the automation rate and thus efficiency and flexibility. Today, the added-value in process optimization through Fastems MMS control are very significant and based on the capacity for autonomous and goal-based operations.

Fastems has developed a standardized cell for robotic finishing (RFC) for standalone or FMS integrated operations

Exclusive focus on high-mix automation

During the last decade Fastems has also decided for exclusive focus on its automation solutions for CNC manufacturing. In 2014, the Finnish machine tool and robot import businesses were separated into a dedicated company (Machine Tool Center). Fastems also divested all its OEM businesses for sheet metal and robot cells as well as tooling. The last machine tool built by Fastems was delivered in 2004 and in 2022, Fastems has signed an important contract with special machine tool manufacturer Metecno for the aftermarket services for all legacy Fastems (or predecessor) machine tools.

The last Fastems special machine tool deliveries took place in the early 2000s.

More autonomous, effective and easy automation, Towards 2030:

Until 2023 the company has installed over 5000 automation systems on all continents: the majority are in Europe, North America, and China. References from the most prestigious OEMs and also local machine shops, leading control software and offering combined with integration capabilities and full-stack service are what make Fastems a unique automation partner. We’re constantly navigating the technological domain of CNC manufacturing to build solutions that embody the latest and best ideas.

Today, CNC manufacturing is facing an increasing level of complexity: more product variants, more complicated parts, more demand shifts, and tighter lead time and quality requirements. In addition, there are challenges with finding people, near-shoring, and sustainability. These trends are expected to continue until 2030 and beyond. When it comes to automation, the biggest emerging trends we see deal with increased automation and connectivity levels, meaning that manufacturing becomes more transparent, optimized and data-driven.

Intelligent CNC automation is an appropriate answer on today’s high-mix manufacturing challenges

With the help of modern production planning software, autonomy also increases as rule-based automation is replaced with goal-based automation. The shift is possible only if automation is in total control of the manufacturing process, through manufacturing management software (MMS), which runs the production and guides the operators according to customer order delivery needs.

As for the challenges, one of them is making sure all this evolving technology is accessible to the market. Despite the decade-long hype, especially in high-mix manufacturing, the opportunities in automation are not yet realized often enough. This calls for productization, thought leadership in promoting the latest concepts in an understandable way and partnership that support automation execution.

Want to know more? Contact us!

If you’d like to learn more about Fastems, don’t hesitate to be in touch!

"*" indicates required fields