MLS –

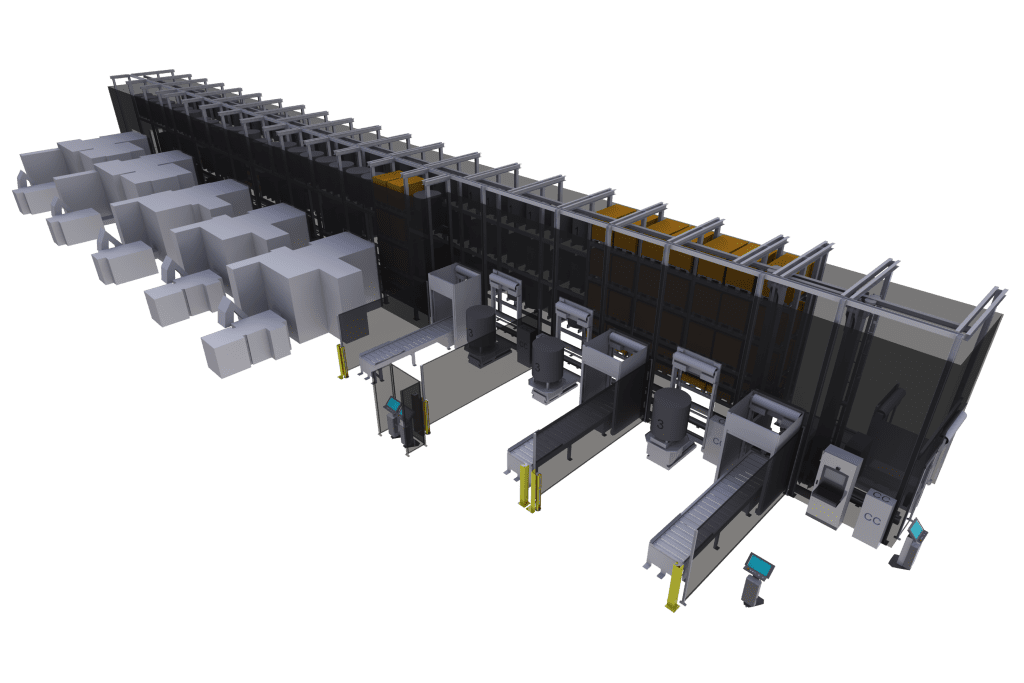

Multi Level System

What is MLS?

MLS does it all

Looking for a tailored flexible manufacturing solutions to integrate and automate any machine tools and value-adding processes together? Have a need for tool automation? Large or heavy pallets? Appreciate various loading stations options?

Fastems MLS handles even the most demanding and complex manufacturing settings: it manages tools, finishing processes, quality control, automatic fixture loading (and manual machine tool scheduling). It comes with a wide range of loading and material stations. Payloads vary from 500 to 11 000 kg.

MLS utilizes the full module stack of industry’s leading manufacturing control system, MMS, with predictive scheduling and production execution.

BrochureWhy MLS?

Mix pallet and tool automation with finishing processes

Intelligent production planning and scheduling software

Multiple machine tool types in one automation system

See MLS in Action

What you gain

MLS Benefits:

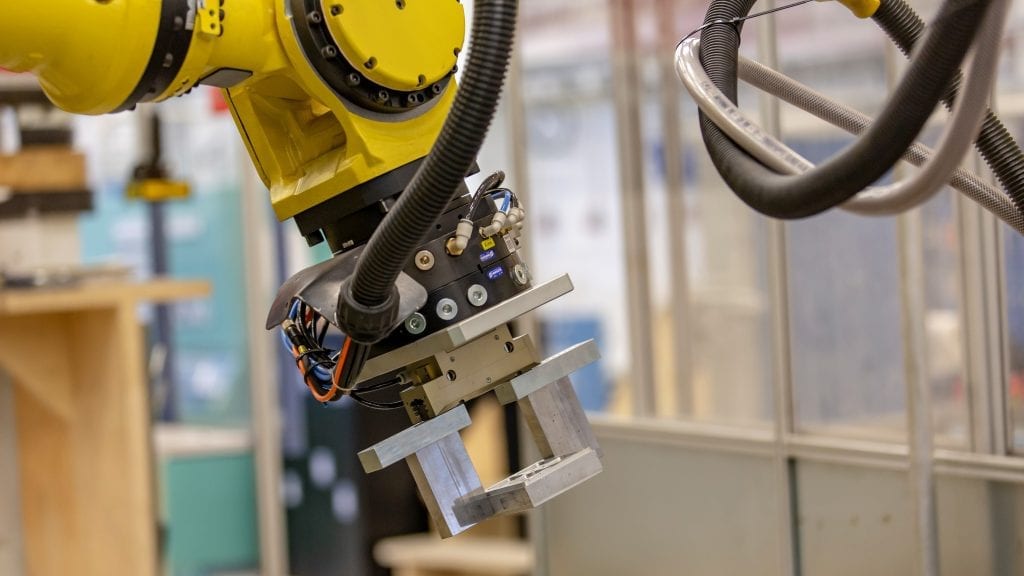

- Automation solution for every 3 to 5 axis machine tool

- Easy and straightforward extendability

- Great user ergonomics and intuitive operations

- Material logistics integration

- High pallet transfers per hour-capacity

- Ready for robotic applications

- Ready for customized integration

Optimization

Manufacturing Management Software

MLS comes with industry’s finest production planning and execution software, MMS. Manufacturing Management Software is always one step ahead by automatically calculating the optimized production workflow and necessary resources, including tools, based on orders.

MMS adapts automatically to changes in the daily production schedule and displays information to maintain the production output.

Auxiliary processes?

MLS Integrates With

Need support?

Services for MLS

- 8760 support

- Service agreements

- Maintenance

- Spare parts

- Upgrades

- Relocations

- Training & Consultation

- Consultation

Technical Data

|

Feature |

LD |

MD |

MDR |

XMD |

HD |

XHD |

SCR |

Special |

| Load weight (kg) | 700 | 1500 | 1700 | 3000 | 6000 | 10000 | 2000 | Custom |

| Machine pallet size (mm) | 400-500 | 500-630 | 500-630 | 630-800 | 800-1250 | 1000-1600 | 630-630 | Custom |

| Maximum load size (mm) | 800×700 | 1250×1250 | 1125×1125 | 1600×1400 | 2700×1700 | Custom | Custom | Custom |

| Load height (mm) | 900 | 1250 | 1450 | 1700 | 2000 | Custom | Custom | Custom |

| Stacker crane load handler | Parallelogram | Telescopic forks | Rotating Handler | Telescopic forks | Telescopic forks | Telescopic forks | Double stroke rotating | Custom |

| Material pallets in the same system | Option | Option | Option | Option | Option | Option | No | Option |

| Number of integrated machine tools | Unlimited | |||||||

| Brand of machine tools | Any machine tool brand available on the market | |||||||

| Number of pallet places | Unlimited | |||||||

| Control system | MMS | |||||||

"*" indicates required fields