CNC Automation for the Pump, Compressor and Fluid Power Industries

Profitable and Flexible CNC Manufacturing for Pump, Compressor and Fluid Power industries

Automating the CNC manufacturing of parts for pumps, compressors and fluid power industry makes production profitable and flexible at the same time. Automation enables high spindle hours and resource utilization, fast and reliable lead times, constant quality, full traceability and proactive production planning for flexibility even when facing sudden changes. Want to know how? Download our CNC automation guide from below!

Fastems is the leading supplier of CNC automation solutions for batch manufacturing. We’re an open-integrator with over 40 years and 4000 systems worth of experience – lot’s of it around pump, compressors, hydraulics, valves and similar parts. We integrate your CNC machines and supportive processes to one highly productive unit operated with our industry-leading MMS control.

Get your free CNC automation guide

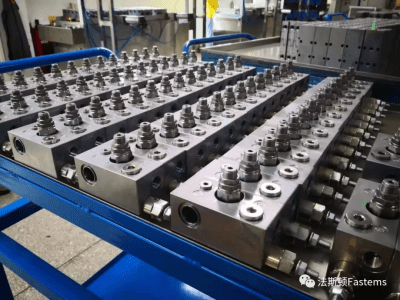

Typical Applications for Automation within the Industry Include Parts for:

- Pumps

- Compressors (e.g. impellers, chasings)

- Hydraulic components (e.g. hydraulic blocks)

- Pneumatic components

- Valves (e.g. directional valves)

- Actuator parts

See our Pump, Compressor and Fluid power industry Case Stories

Production Challenges and Automation Benefits:

- More customization and amount of variants

- Shorter lead times and planning horizon

- Costs & tied capital reduction

- Demand variance

- Traceability needs

- Availability of workers

- Constant quality

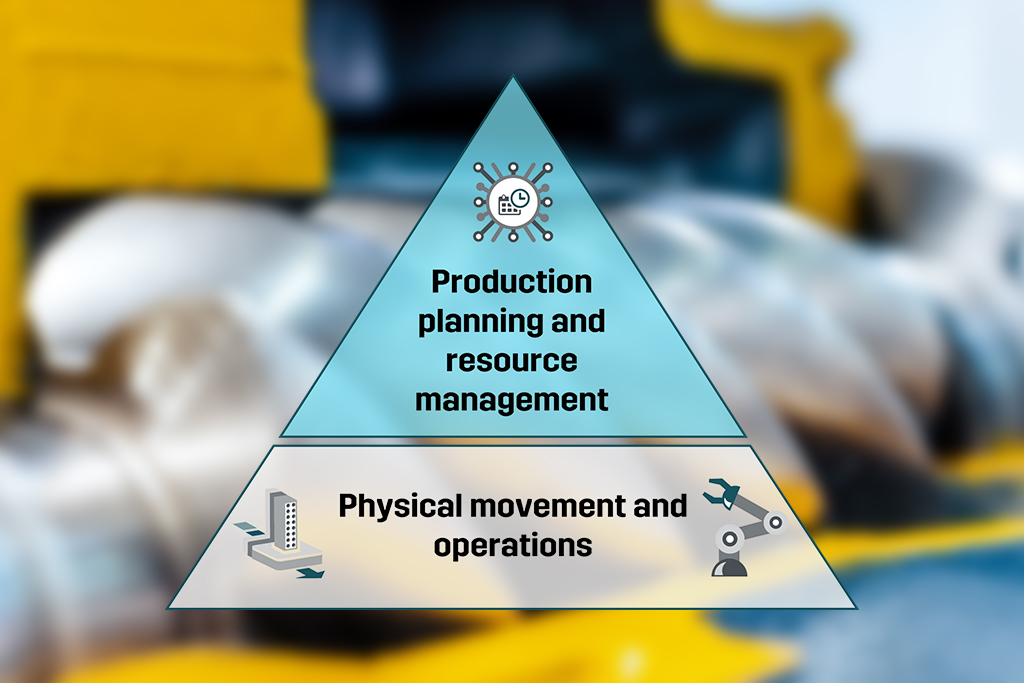

Automate Production – Not Just Movement

Learn how to get the most out of your CNC machines and other equipment in pump, compressor and fluid power industries. Apply batch production automation best practices summarized below:

- Stabilize and integrate manufacturing process steps

- Automate physical part transfers throughout the value chain

- Benefit from automated, intelligent production planning software

Solution Finder

Our automation solutions are highly suitable for the needs of the fluid industries, and by using our solution finder below you can find the right solution for your production needs. We are also an open integrator, so if you didn’t find what you were looking for, just contact us directly and we will help you find the right solution for your production needs.

Didn’t find what you were looking for or have questions? Contact our professionals!

Filter by

Machine tool or process type

Filter by

Qty of machines

"*" indicates required fields