When running a shop floor that requires a large variety or considerable amount of highly expensive tools, or when the tools needed have short service times, you’re likely to run into some challenges. Manual work is required to change the tools, which means there’s always potential for human error. Not to mention the costs of stopping production during setups. Sound familiar? If that’s a yes, we encourage you to check the following points on what the benefits of Fastems tool automation are and how it can help you maximize machine utilization and increase productivity.

Have Tools Available Just In Time

Even short tool wait times can end up being expensive losses in production. An operator might forget to take a tool to a machine – a simple mistake that can cause a substantial delay. This makes having the right tool in the right machine just in time essential to keep machines running smoothly. Luckily, Tool Automation will take care of all of this for you, while maximizing usage of the tools. That is, when tools move flexibly between the tool storage and machines, you don’t need to worry about delays.

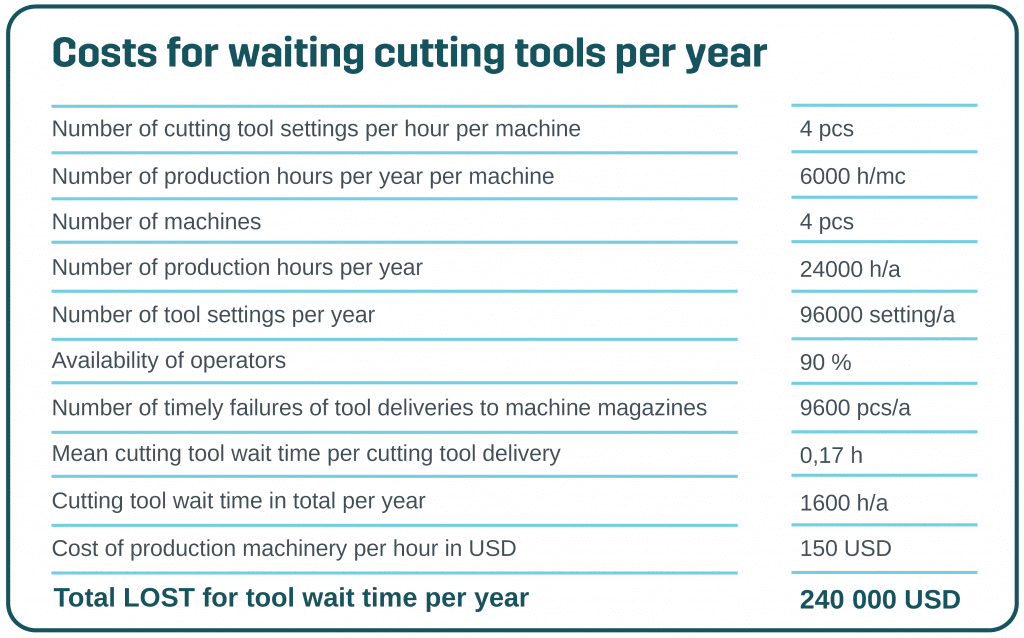

Let’s have a look at an example calculation of possible losses due to tool wait time:

Tool Data and Human Error Free Production

Even the smallest errors in tool data input or manned tool management can cause significantly negative consequences. Stefan Kempf, CEO of Norbert Kempf CNC-Technik, identified tool management to be a considerable source of errors in production, and therefore decided to invest in human error free production with Fastems Tool Automation.

“At the time, we had about five retoolings a day, 250 manual transports for tooling, 40 to 50 tool transports due to wear, and an average of six clamp assemblies. All these activities had a lot of potential for mistakes, and tool management in particular turned out to be a major source of errors,” explains Stefan.

With Tool Automation, tool data comes automatically from the presetter, which means operators don’t have to input tool parameters manually. It enables error free production, in which the role of the operator shifts to co-worker or manager of the automated manufacturing process.

Schedule Your Upcoming Tool Needs with Our One of a Kind MMS Control

What makes Fastems’ Tool Automation special, is the industry’s most advanced production planning and execution software, Manufacturing Management Software. MMS is always one step ahead, because of how it automatically calculates the optimized production workflow and needed resources based on orders. This minimizes the amount of hassle on the factory floor – operators always know in advance what tools and raw materials are needed now, and in the future.

With MMS, machine control integration allows a machine tool to start machining, even if all the required tools are not in their magazine. Moreover, if there is a change in production, MMS adapts to it in the daily production schedule and displays information to maintain the production output. On top of all that, MMS is easy to use, integrate, and can be configured to meet individual needs.

Increase Productivity and Reduce Costs

Increased spindle utilization always differs depending on the starting situation. But to give you an idea, for FMS with 80-85% utilization, tool automation can lead to growth as high as 20%, meaning a running productivity level of 90-95%. What’s not to love?

Increased productivity also reflects in savings. Tool costs become smaller due to the decreased amount of redundant sister tools in total. Also, smaller ATC tool magazines in machine tools lower the amount of needed machine tool investments. Savings also come from labor costs, as processes and logistics are organized and tool planning is automatic. Finally, tool automation also improves capabilities in tooling development due to monitoring and reporting functionalities.

Just in time tool availability, combined with no human errors or missing tool data and the MMS is what makes Fastems Tool Automation a one of a kind. If you’re looking to increase productivity and maximize the utilization of your machines, check whether Fastems CTS or GTS could be the solution for you.