A traditional challenge in manufacturing smaller batches economically is the time (and money) consuming machine tool setup changes between batches. Setup changes require operator intervention and stopping the machine to change or rebuild the fixture or tooling. Therefore, this blog series will introduce three technical approaches on how to make small series production more economical – starting with the part fixturing to machines.

1. Load workpieces faster

The first step in cutting setup-time of machining centers is equipping the machine with an automatic pallet changer (APC). Next, pallets need to be buffered in a pallet pool or flexible manufacturing system.

The first step in cutting setup-time of machining centers is equipping the machine with an automatic pallet changer (APC). With the changer, setup-times can be partially carried out on the APC side of the machine, while the previous work piece can be being machined in the spindle side. Next, pallets need to be buffered in a pallet pool or flexible manufacturing system. However, neither of these systems offers automatic part loading / unloading, so to decrease the need of human intervention, material handling should also be automated.

2. Automate the setup changes

Material handling should be automated to decrease the need of human intervention and related costs.

Luckily, fixture suppliers have introduced products with which setup changes can be automated and thus done during the fully automated period.

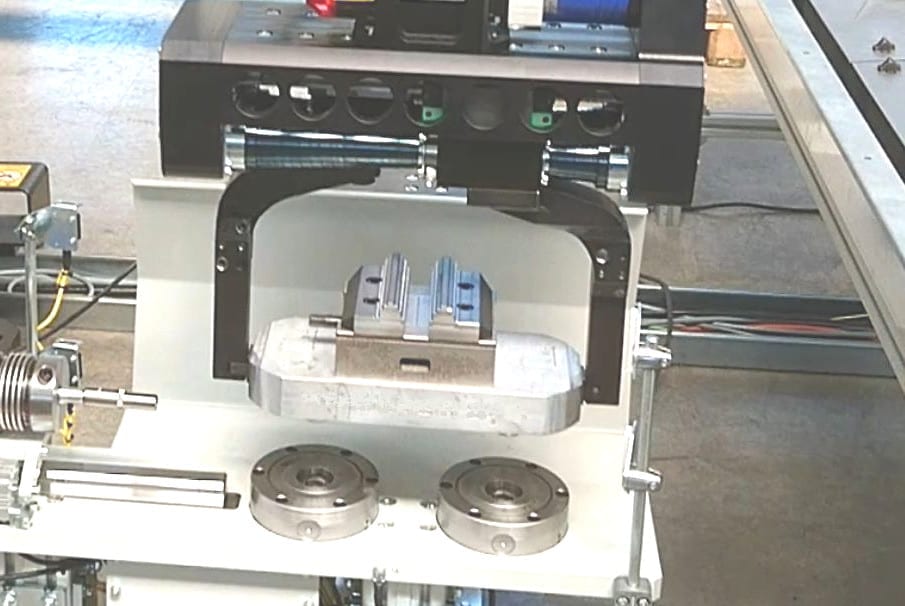

Naturally, the fully automatic setup change causes certain limitations to the manufactured products. If machined parts can be limited to some geometrical similarity (like cubic part in some limited part size range), the solution can be a standard and cost efficient long stroke screw vise, which can be opened and closed with a servo motor. Such a servo system is available as a product from the company Allmatic, for example. If the vises are equipped with interchangeably formed jaws, the part variety can be increased even further. We at Fastems promoted a similar system at EMO 2017, but with a hydraulic fixture together with clamping solutions company Polund (watch a video here).

3. Combine pallet and part automation

Direct part loading / unloading not only saves the operator time to more productive tasks, but can also lower the needed fixture investment.

If the part variety cannot be simplified but there’s no constant need of introducing new part variants to the production either, the exchange of the part fixture can be automated with the same robot that handles the part loading and unloading. This is a valid option if the weight of the empty pallet can be held under approximately 500 kilograms. This allows combining the best of the traditional FMS system by changing the machine fixture setup quickly, with the benefits of a conventional part loading / unloading robot cell. Loading of the part can either take place outside or inside the machine, depending on the machine type and characteristics of production.

Of course, the time used for setup change will lower the machine utilization rate – but on the other hand the system will be able to produce parts that can be delivered immediately, thus generating instant turnover instead of increasing stock value. In comparison to traditional FMS operations, using direct part loading / unloading not only saves the operator time to more productive tasks than part loading, but can also lower the needed fixture investment. This is because the fixtures do not necessarily have to be designed to hold as many as parts as possible to keep the number of fixtures low but still to be able to produce greater variety parts.

Direct part loading / unloading not only saves the operator time to more productive tasks, but can also lower the needed fixture investment.

All the solutions mentioned in this post are applicable only in machining centers. If you happen to need turned parts, the fixturing solutions are somewhat different. Luckily, all major chuck manufacturers have already introduced jaw systems for quick manual jaw changes, and most of them already offer a variant of the same system which is meant to be changed with a robot. If the part diameter and thus the required spindle RPM varies a lot, even the chuck can be automatically changed to allow different spindle speeds.

This was about fixturing – in the next post I focus on how the production of smaller batches can become more economical with robotics.