In the last post of economical small-batch production series (the earlier posts focused on Part Fixturing (part 1) and Gripping Methods (part 2) I focus on the software and NC programming which should be pretty much rethought when moving towards very small batches or pure 1-offs.

“First time right” with advanced NC programming

If the parts to be manufactured are true 1-off –products, meaning the batch is manufactured only once and the part is hardly likely to be made again, causes this quite a bit of pressure to NC Programming. As the programs can’t be fine-tuned by someone standing next to the machine, must the CAM programming capability be developed to the level where new NC programs are done offline “first time right”. This requires a lot of work and learning, but I have met already a few companies where this has been realized. Key factors to success seem to be (1) well selected CAM-software, (2) collision detection and most critically, (3) well trained CAM programmers.

Control software reduces the production planning work

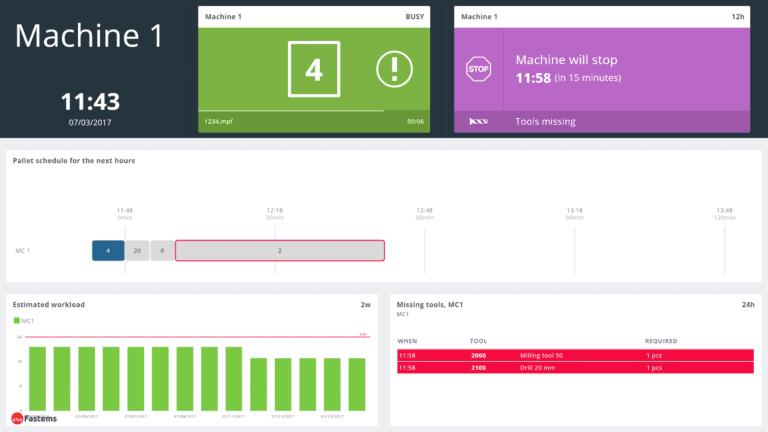

As scheduling small batches easily increases the workload of production planning almost in the same scale as the amount of production batches increases, it is the best to give the task of detailed production planning to a control software. In our offering the solution is Manufacturing Management Software (MMS) control suite, which plans the production to the future and ensures that the order due dates are met by showing the resource needs and scheduling the manufacturing of batches based on resource availability. Control software provides also a great help in arranging the required tooling to the right machines to avoid the tool shortage stopping the production, especially in cases where the tool capacity of the machine tool is limited. The same applies also to required materials, which are easily arranged to the right place in right time according to the scheduling information of the control software.

By combining suitable fixturing techniques, advanced grippers with capable control software and advanced NC programming it is possible to manufacture smaller manufacturing batches and even pure 1-off products economically and fully automatically – at least inside of certain scope of the total product range.

For an additional read, I recommend the excellent blog post by Mr. Kallin Kurtz: A Systematic Approach to Developing Automation for Low Volume, High Mix Machining.