Succeed in High-mix CNC Automation

Make Time Work for YOU

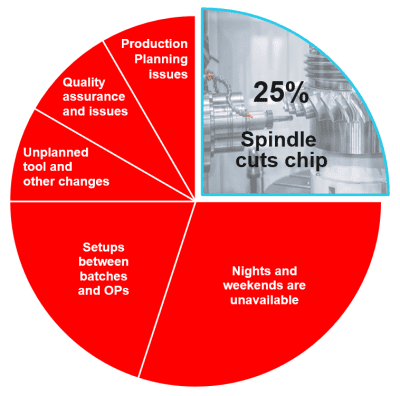

In batch manufacturing the average CNC machine cuts chip only 25% of available production hours. Want to know how to reach 80% and beyond?

Take the first step and download our checklist for your high-mix automation success.

Main Reasons for Low Machine Utilization

Inefficient set-up changes

Your machine tool requires not only the raw material but also correctly measured cutting tools, verified NC programs and accrurate workholding to run quality parts. It can take hours or even days to set up the next job in a machining center. And the higher your production mix, the more the set up process eats your spindle time.

Unavailable Nights and Weekends

Nights and weekends count over half of the potential spindle capacity in a year. In a high-mix machine shop, CNCs are typically idling overnight due to the need to run more than just one part – and the difficulty of automating those setup changes.

Insufficient Flexibility for Sudden Changes

Changes are part of our everyday life. When a rush job arrives, your CNC breaks or your raw material delivery is late, you need to adjust. You react: re-plan your production, re-route the most urgent jobs, order maintenance – and when you need to react, you lose spindle capacity.

Flexible Automation Changes the Game

“As the shop’s production mix and volume grew, the time required to construct multiple setups grew as well. Once Mr. Olsen realized that monthly setups took an employee four hours to complete he decided it was time to invest in CNC automation.”

Mach Machine, US

Learn How Flexible Automation Makes a Difference

Download Our Ultimate High-Mix Automation Checklist

To help you to get ready for CNC automation, we have condensed a free five-step CNC automation checklist. This comprehensive checklist is a recipe for success in automating high mix manufacturing – tested and verified by thousands of metalworking manufacturers already. Download yours!

"*" indicates required fields

Learn More

Want to Hear More?

Contact your local expert!

"*" indicates required fields