Difficult to cut materials, a high number of cutting tools or machines, expensive tools, short tool lives – if you recognize any of these in your machine shop, you might want to learn about how tool automation could improve your business. Our previous cutting tool post touched on improving quality and reducing scrap by integrating a tool presetter with the production control system. In this post we go into tool automation!

In simple terms, the idea of tool automation is to schedule and share tools between multiple machines in order to:

improve machine tool utilization and lights-out production time,

invest less in sister tools and large machine tool magazines,

reduce the manual work around tool transfers, and

remove tool mix-up errors.

How does it work in practice?

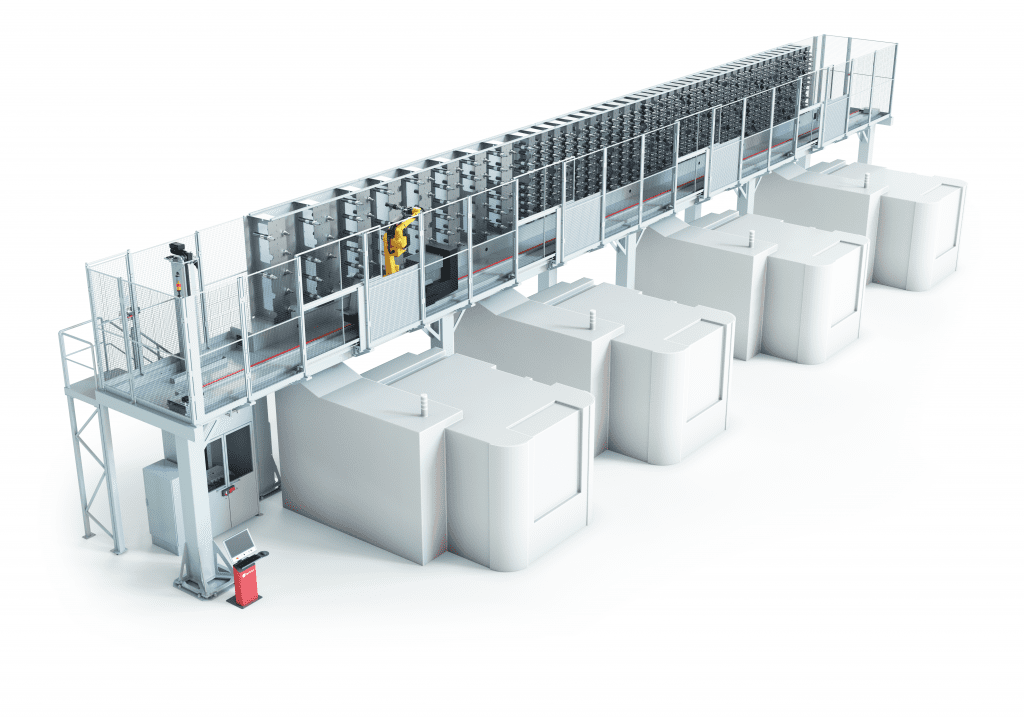

In centralized tool storage systems, pick-and-place and traveling gantry robots provide access to a centralized storage of up to 6,000 cutting tools. This allows for just-in-time tool delivery to individual machines. Manufacturing Management Software MMS commands automatic cutting tool changes based on specific NC program scheduling requirements and real-time cutting tool life status. The system shows the exact tool needs up to 4 days in advance, and automatically brings worn out tools to reworking. This is then the only thing that the operator needs to take care of (unless the 4th level of tool management is implemented, but more on this next week). The tool storage can be either placed on the shop floor (Central Tool Storage CTS) or to save floorspace, above the machines as a gantry (Gantry Tool Storage GTS).

Machine tool utilization up to 90% + increased lights-out time

With a centralized tool storage, cutting tools do not create a need for machine dedication. MMS plans and runs production based on real-time information on production orders and their due dates, and available cutting tools plus their condition. With no need to do any manual planning or transfers, all the machines and cutting tools can be utilized at maximum level, also unmanned, and orders are finished just-in-time. Typically, our customers with flexible automation and centralized tool storage reach machine tool utilization of around 90%.

Reduced sister tool and magazine investment

Often jobs are dedicated to machines due to complex and laborious tool management. The only way to avoid job dedication without a tool automation system would be purchasing large machine tool magazines and a lot of expensive sister tools. When adding more tools, one needs a larger magazine, which often is very expensive. With tool automation, thriving with small machine tool magazines is possible and generates significant cost savings in machine tool investment. On the other hand, the need for sister tools reduces, generating savings also in the cutting tool investment phase.

If a cutting tool costs 500€ on average and you have 1,000 of them, your tool investment would be 500k€. Plus, what is the cost for several hundreds of tool pots per machine? What if you could reduce both by 30-50%?

Reduced manual work around tool transfers improves ergonomics and quality

Safety and ergonomics are two of the most important factors on any shop floor. Transferring tools manually is not only time consuming but also repetitive, which can cause a lot of physical strain. In addition, when tools are heavy and sharp the work can quickly become less than ergonomic or even dangerous.

With work like this that is repeated tens of times a day, it’s only natural that errors occur every once in a while. With a centralized tool storage, the operator can invest time to more meaningful tasks and trust the system to make the “easy work” faster. In sum, tool automation improves both production ergonomics and quality.

The only thing the operator needs to take care of in level 3 of cutting tool management is the tool reworking. In our upcoming and final cutting tool post, level 4, I will present an exciting addition to Fastems’ offering: Tool Service Cell (TSC), which also automates the majority of tool reworking. Until next week!

P.S. Do you want to calculate YOUR shop floor performance and how much you could save by implementing some of the tool management practices we have presented? We make automation ROI calculations with our customers all the time. Feel free to contact us if you want to book your shop floor a math lesson!

Also, if you are interested understanding all four levels of the best cutting tool management practices in more detail click here. In addition to that, be sure to register for our upcoming virtual seminar. This will be a day of educative webinars, video demonstrations and Q&A sessions on several productivity-related topics, including cutting tool management.

Register for our virtual seminar

"*" indicates required fields