Tool Automation

Enable Continuous Machining in High Tool Demand

Do you need a lot of cutting tools to run your NC-programs? Do tool changes eat your machining time? Does your team need to constantly work for sufficient tooling? Do you have errors in tool loading?

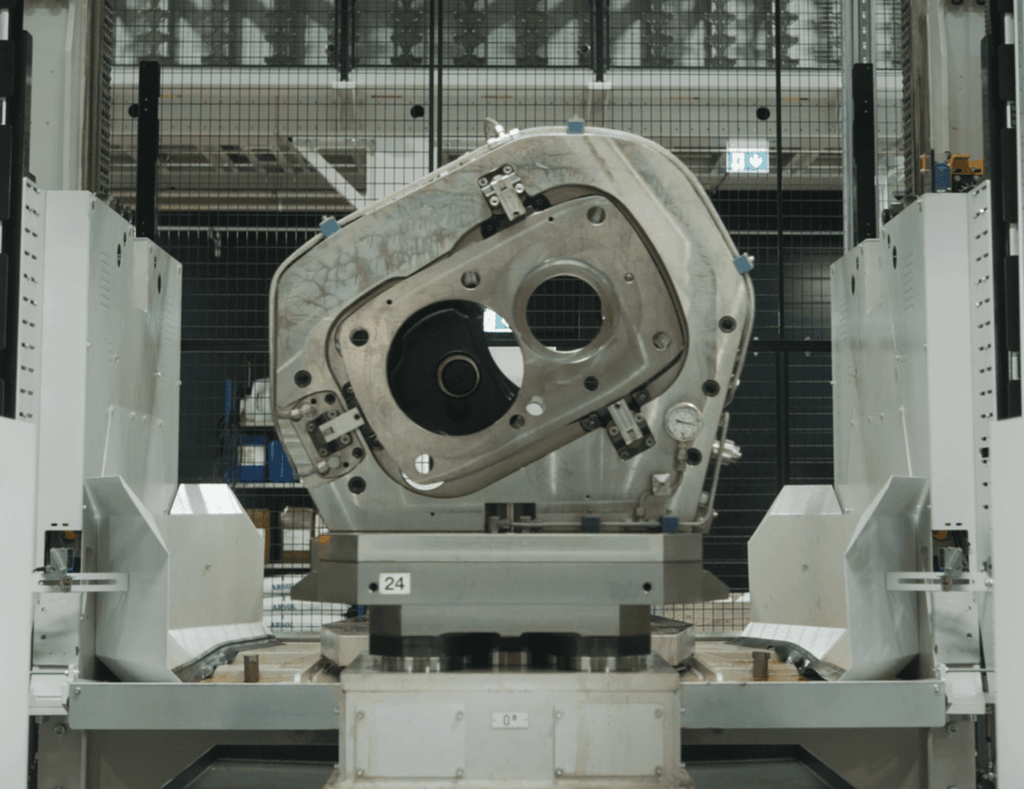

Tool automation is the solution to eliminate the above inefficiencies – it stores large number of cutting tools centrally and transfers them to machining centers just in time. With tool automation, you can extend your lights-out machining capacity, secure tool availability, reduce errors, and minimize your capital investment in cutting tools and magazine pots.

What Is Tool Automation?

The idea of tool automation is to transfer cutting tools between a central tool storage, your machining centers and maintenance – just in time. This means three things:

All your machining centers can share the same set of tools – you need less sister tools. Since you store most of the tools outside your machine, you can purchase smaller machine tool magazines.

Tools can be brought in the magazine during the NC-program – your machine starts running once it has the first tools. You can count the robot to bring in the later needed tools while the NC-program proceeds.

Worn-out tools are automatically delivered to tool maintenance – your team has one easy and ergonomic access point to tools, and full visibility on which tools need to be preset by when.

Tool Automation Solutions

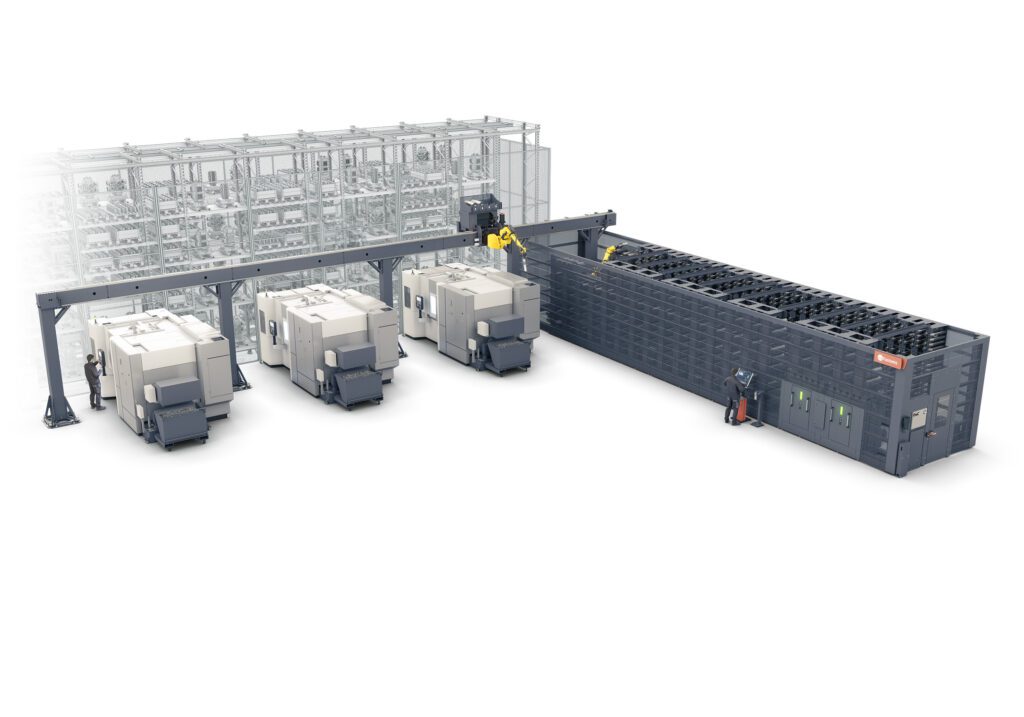

Our first tool automation systems were delivered 25 years ago. To ensure fit for every need and maximize the use of available space, we offer two options: the compact Gantry Tools Storage System (GTS) and Central Tool Storage (CTS), which offers greater tool capacity.

Gantry Tool Storage GTS

The compact Gantry Tool Storage is utilizes the vertical space of your facility and operates above machining centers.

- Space-efficient and configurable gantry tool storage above machining centers with capacity for up to 1,500 tools

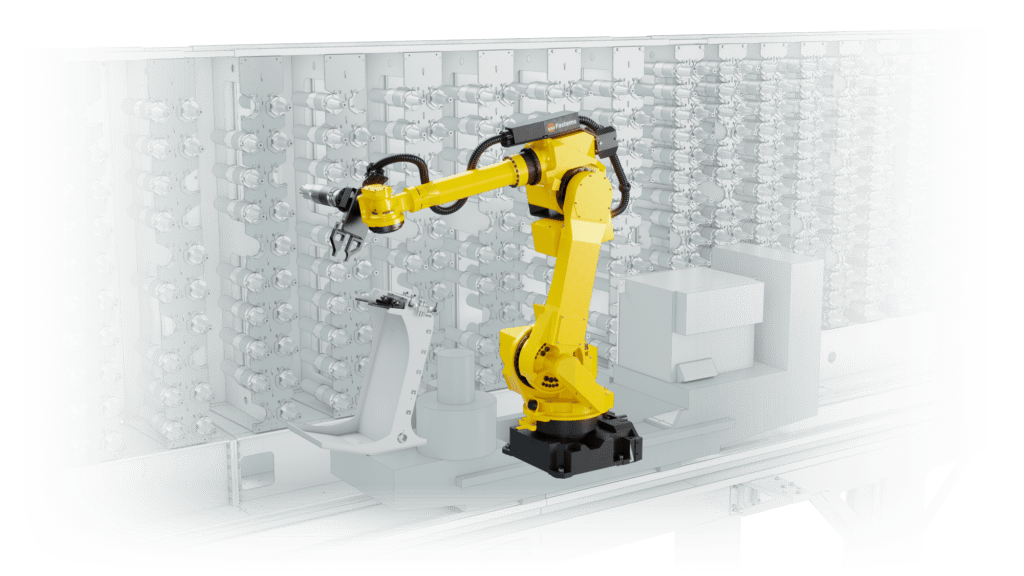

- Gantry robot to transfer tools to machining centers

- Tool lift to bring worn-out tools to ergonomic floor-level tool station where operators can take them out and bring back in after presetting

- Manufacturing Management Software MMS to schedule, run and monitor cutting tool transfers and processes based on machining schedule

- You can use the system together with CNC automation or stand-alone.

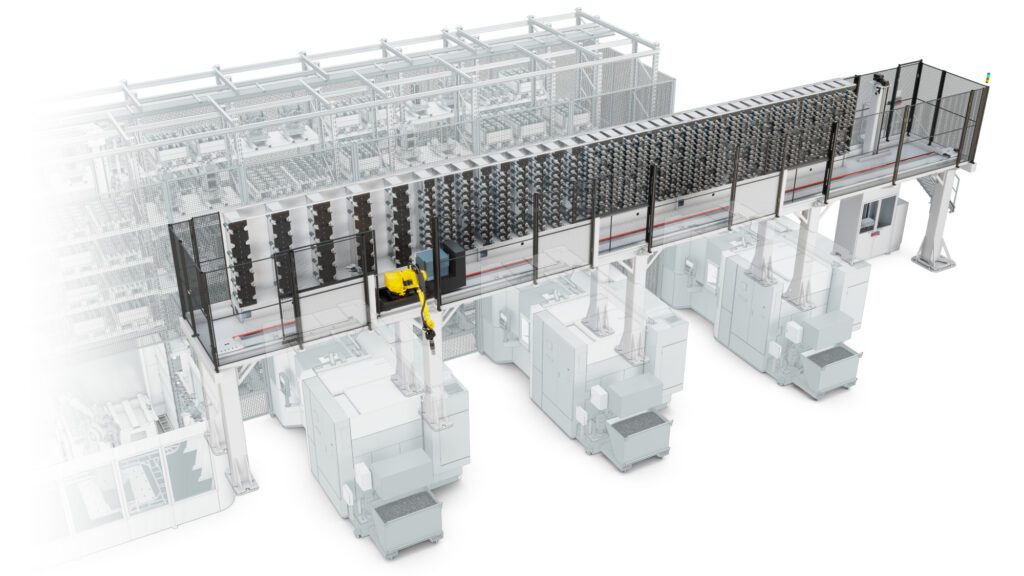

Central Tool Storage CTS

Central Tool Storage extends to even the most challenging needs with extreme number of tools.

- Configurable floor-level tool storage with capacity for up to 5,000 tools

- Gantry robot above machining centers to transfer tools to and from machining centers

- Ergonomic tool station(s) for operators to take worn-out tools out and bring maintained tools back in

- Manufacturing Management Software MMS to schedule, run and monitor cutting tool transfers and processes based on machining schedule

- You can use the system together with CNC automation or stand-alone.

How Does Tool Automation Function?

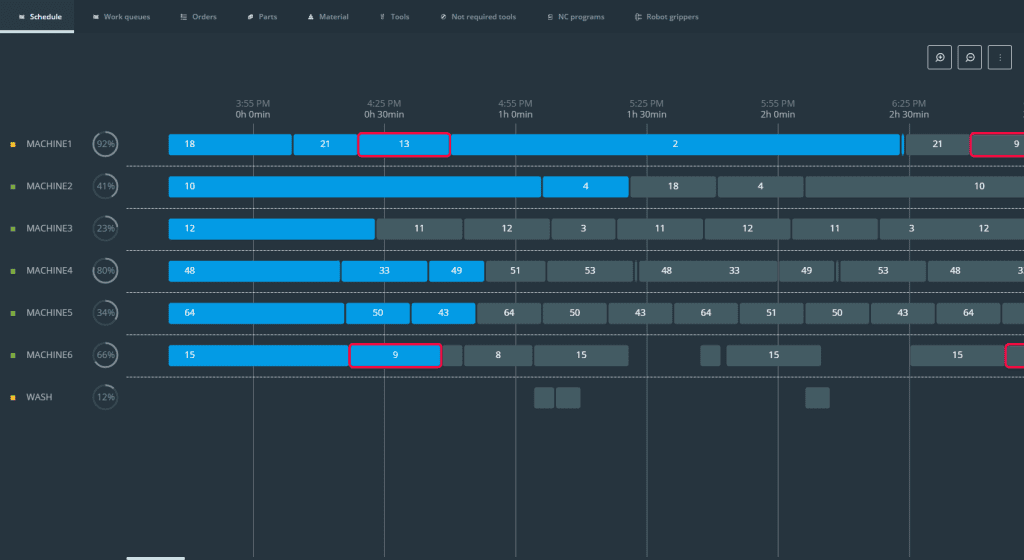

MMS, the control software of all Fastems automation systems – including tool automation – is designed to manage even the most challenging tool processes. It supports everyone working around tool processes, giving a real-time view on what happens in production and most importantly, identifying exactly what needs to be done next to ensure timely deliveries and maximum spindle utilization.

1 | Plan Production

MMS schedules manufacturing and checks which tools the NC-programs will need during the coming 96 hours. It creates a tool schedule and informs operators in advance if some tool is missing.

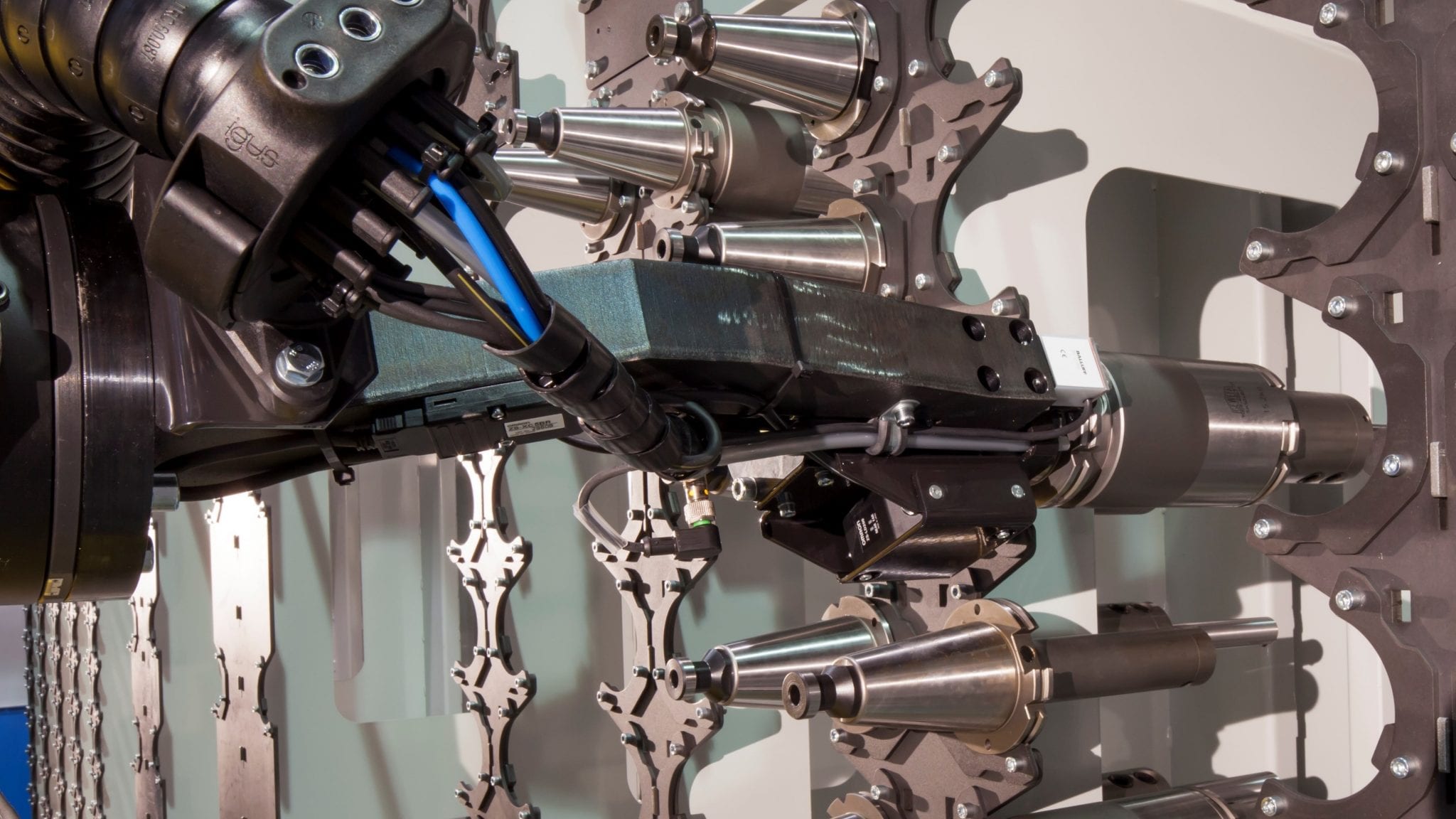

2 | Deliver Cutting Tools

Gantry robot delivers tools to magazines just-in-time. The machining begins when first tools of the NC-program are in – the next ones are automatically delivered as the NC-program proceeds.

3 | Bring to Presetting

The worn-out tools are automatically brought to tool station where operators can take them out and bring back in after presetting. From MMS tool presetting list, operator always knows which tools to preset and by when.

4 | Monitor & Develop

MMS monitors and reports about your tool usage in real time. It tracks your selected KPIs and gives useful information such as lists of bottleneck tools, often breaking tools and the least used tools.

ADD TO YOUR SYSTEM

Tool Service Cell TSC

Are tool maintenance and presetting a bottleneck in your machining process? You can integrate Tool Service Cell TSC into your tool automation system, and enjoy:

1. Faster, timely and automated tool service handling,

2. Reduced operator time needed for tool maintenance, and

3. Great safety and ergonomics with no heavy tool lifts.

Tool Automation Customer Stories

See how other manufacturers have automated their cutting tool processes and reached amazing results!

CENTRAL TOOL STORAGE CTS

KEMPF CNC TECHNIK: “We have 1,000 tool transports per day – and spindle utilization above 90%.”

GANTRY TOOL STORAGE GTS

INGERSOLL RAND: “We automated short machining cycles requiring up to 70 tools each.”

GANTRY TOOL STORAGE GTS

WÄRTSILÄ: “From raw materials to finished parts, we have fully automated our single-piece flow.”

GANTRY TOOL STORAGE GTS

GILBERT PRODUCTS: “We can begin machining even if the 15th tool is being used elsewhere.”

CENTRAL TOOL STORAGE CTS

BAE: “Spindle utilization has been raised from 60 to around 90 %.”

Watch Our Tool Automation Webinar

Learn the basics of tool automation – what is it and for who, how does the solution build, and how to calculate ROI.

"*" indicates required fields

Contact Us

Give us a call or send an email.

"*" indicates required fields