Without walking through your production machine by machine, do you know if your customers’ orders are on time? If the answer is yes, you can congratulate yourself – your production is digitalized! If you answered no, I recommend reading further.

A few weeks ago, I met a production manager of a highly automated subcontracting workshop. Even though their manufacturing was automated, the only way to follow delivery reliability, their key performance indicator, was by having the production manager discuss the overall status of the production and customers’ orders with every single operator in the factory. Because of this, he had to spend a considerable amount of time in production just to re-schedule jobs, double-check the orders and solve challenges at hand.

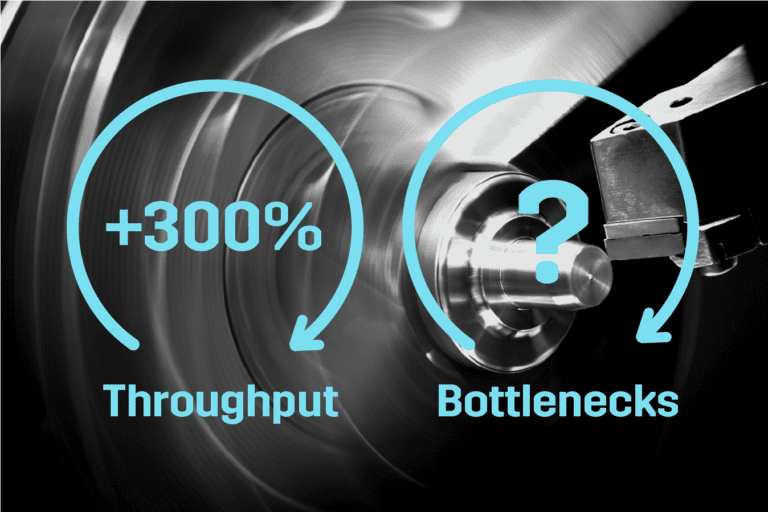

This problem is very familiar in non-automated factories, but why does it occur in a highly automated factory? High automation levels enable high production throughput, which is a good thing. However, the consequence is that the production issues and bottlenecks occur even more often. It is almost paradoxical how automation triples the throughput, but can also triple the amount problems if IoT is missing.

How does IoT help? It brings intelligence to the production and enables the automation system to predict and tackle upcoming challenges and possible bottlenecks before they even occur. Modern manufacturing means seamless cooperation between the intelligent manufacturing management software and the automation. The software simulates the manufacturing even days ahead, revealing bottlenecks and resource shortages in advance. The manufacturing management software gets production orders automatically from the ERP and automatically executes the optimal production plan in the manufacturing system after finding the optimal way of producing the orders. If there would be any resource shortages like missing tools, materials or NC programs, the software warns operators hours, even days ahead.

It is almost paradoxical how automation triples the throughput but can also triple the amount problems if IoT is missing.

Order by order, machine by machine, and part by part, modern automation systems let the production manager lean back and follow the production status and on-time-deliveries times from his screen, without walking a marathon in the production. Houston – IoT has landed!

Want to read more? Fastems Blog - Producing lot sizes of one economically