A flexible manufacturing system (FMS) connects machine tools so you can run any part with any of your machine tools. It was designed already in 1980’s to plan and run machining of high part variety, quickly and cost-efficiently. FMS of 2025 can supercharge much more than just machining. How can you ensure automation enhances your overall process, and which FMS device integrations have the best pay-off?

Still today, FMS is often considered only for machining – maximizing the return of machine tool investment. And often that alone already doubles or triples productivity. However, to get the best return for your automation investment, you should consider the overall process from raw material to finished part. Why?

In addition to machining, manufacturing often includes operations such as:

- sawing

- marking

- washing and drying

- surface treatments

- finishing

- quality control

- assembly

- traceability reporting

Manufacturing bottlenecks are challenging to identify. When you automate machining, you might realize some other processes forming bottlenecks as well. Therefore: as part of your automation project, consider how all your process phases:

- have enough capacity that can be utilized effectively,

- play together timely with efficient transfers between them,

- are clearly scheduled and your team guided on what to do next, and

- flow nicely with minimal work-in-progress (WIP) piling up between them.

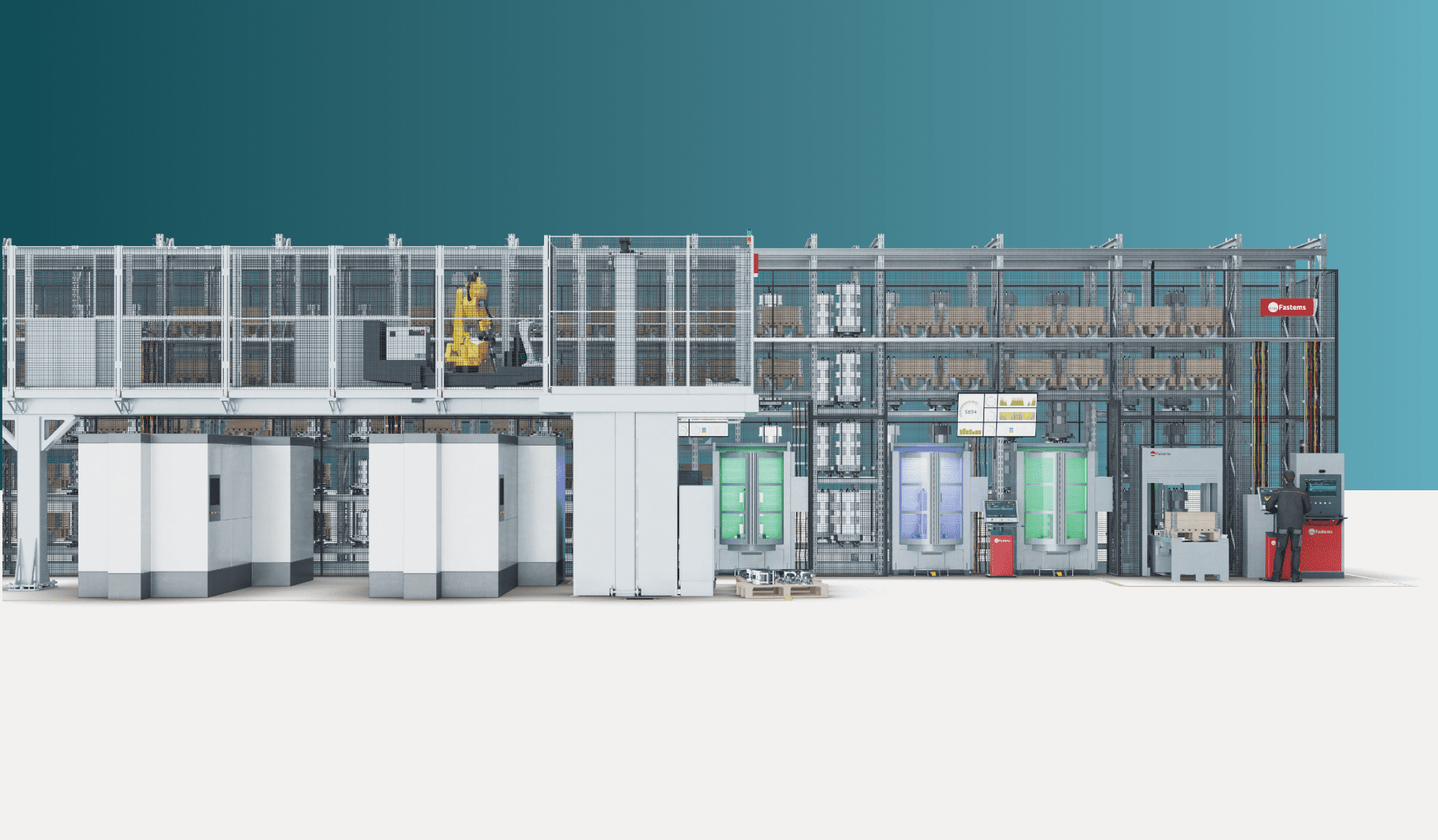

This explains why today’s manufacturers often integrate more than just machining into their FMS. Not only does this reduce the number of manual transfers, but also enables optimal production scheduling and part routing, timely deliveries, and maximized resource utilization. Out of the 5,000 FMSs Fastems customers run globally, here are the five most popular device integrations and their advantages:

1 Finishing

Manual deburring and finishing operations tend to be unergonomic and the part end quality inconsistent. Moving these operations into the machine tool improves quality and safety, but eats part of the machining capacity.

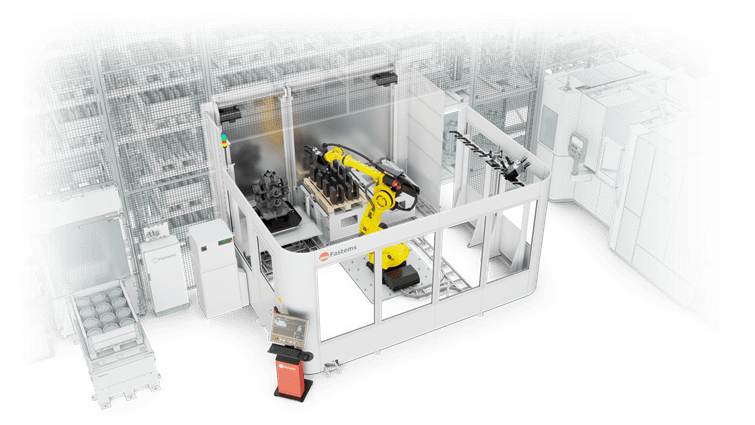

Robotic finishing offers excellent repeatability and consistent quality at a lower cost per part compared to using machine tool for finishing. It is becoming increasingly popular addition to Fastems FMSs with a competitive investment level compared to machining centers.

2 Pallet Auto-Loading – Mix High Runners and Low Volume Production

Many high-mix-low-volume manufacturers also have some high runner parts. Running high-volume parts in FMS is a compromise – either you need an operator to constantly reload new parts into pallets, or you need a lot of pallets (and a large system) to accommodate enough workpieces.

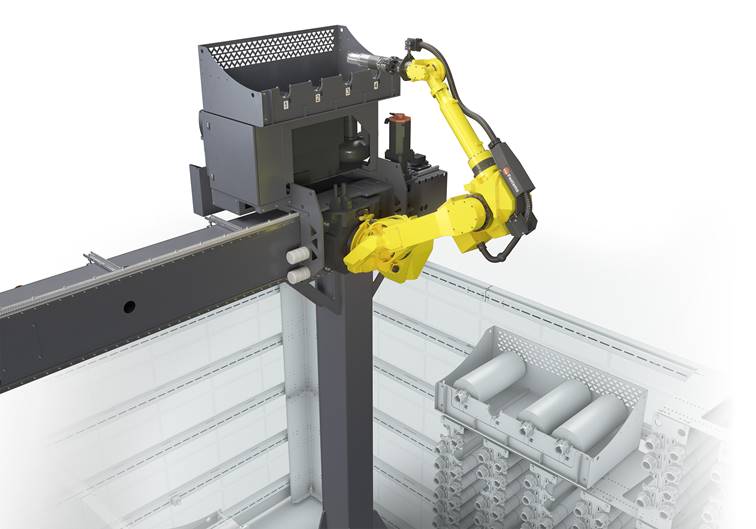

Pallet auto-loading cell (ALD) is a solution specifically designed for this. ALD is a robotic system connected to FMS, clamping and unclamping parts to/from pallets. With ALD, you can automatically take off ready parts and input new workpieces into the same pallet quickly – also when your operators are not there. This reduces the number of pallets and pallet storage positions you need, plus offers excellent lights-out manufacturing capability! Out of Fastems customers, many produce their high-runner parts with ALD over nights and weekends – and the high-mix-low-volume work when the operators are at work.

3 Tool Automation – Enabling Long Lights-Out Machining Periods

Managing cutting tools is often the largest manufacturing bottleneck – it can really limit the machining automation from working efficiently. Tool management and distribution take up a lot of working time for both machinists and machine tools, slowing down overall production and preventing lights-out manufacturing.

Tool automation can store even thousands of tools centrally, sharing them with machining centers based on production needs. Every tool is maximally utilized and since tools are shared between machines, fewer sister tools are needed. Centralized tool storage also reduces the need for extremely large machine tool magazine investments. With the automated tool transfers, you can also run your tool processes partly lights-out. Out of Fastems systems designed today, about one in five include tool automation – and pretty much all include at least the tool management software features.

4 Quality Assurance & Traceability

Quality is a top priority, especially in high-precision machining. And in many industries such as aerospace, defense, medical and heavy vehicles, part traceability is also a must. Both assuring quality and reporting traceability require a significant effort from the shopfloor team – including also a risk for typing errors.

When it comes to ensuring quality, FMS as a technology offers repeatable processes. The quality control devices can be also integrated, whether CMM or another measuring technology. For traceability, FMS records every operation on part-level, from raw material to the finished part, providing an excellent base on which to implement traceability.

5 Washing

Integrating a washing machine or robotic wash into FMS is not really that new. Washing is such a common operation for machined parts and plays a big role in quality assurance that it is typically coupled together with the machining automation. Stand-alone washing typically causes unnecessary WIP and slows down the throughput that would otherwise be short in automated manufacturing.

Since washing machines have been commonly integrated with FMS for decades, there are ready-made interfaces available for most brands, and the return on investment is on a good level. Among all Fastems FMSs over the past 45 years, washing machines of different kinds are still the most integrated devices.

To learn more about the typical non-machining integrations in FMS today, check out the device integration page!

Attending EMO Hanover 2025?

Come visit Fastems in Hall 12, Booth B54 and learn how FMS could integrate your machining and other processes. Our automation specialists are there for you!

Want a Free EMO Day Ticket?

We have it ready for you — just click the button and join us!

To read more about Fastems’ Automate Machining and More showcase, check our event page.