“T6345; 51.003mm; 23.475mm; 27.634mm; 24.30min”. A Post-it note reminds the machine shop operator which cutting tool offsets to put into the machine tool. The operator does this typically tens of times per day. After every use, each cutting tool needs to be remeasured and if a mistake has been made, wrong tool offsets can cause either scrap parts or in the worst case, a spindle crash. Luckily, mistakes happen rarely, right?

Let’s take an example calculation on how many times a year the operator needs to input a lengthy series of numbers and the possible risk for errors:

A company has 4 machine tools,

each runs 6,000 hours a year (24,000 machining hours a year).

On average, there are 4 hourly tool changes per machine (96,000 tool changes a year).

There is a 1% chance of error (960 errors), of which 1% are critical causing a spindle crash (1 spindle crash).

So, what would be the cost of 960 lost parts, including the reworking time? How about a spindle crash?

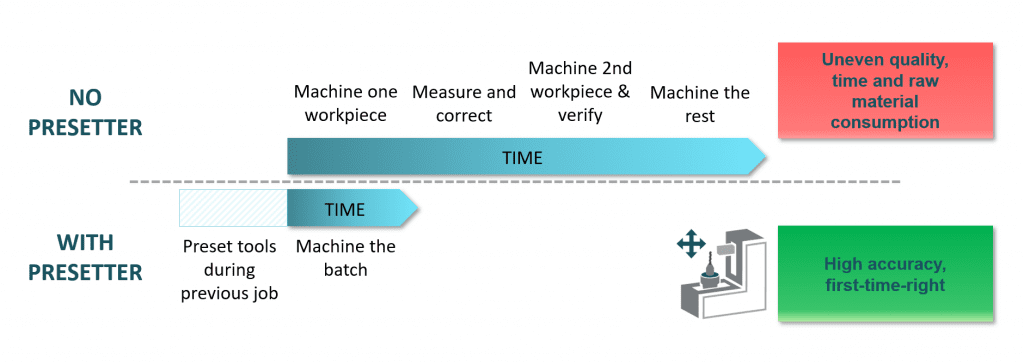

The more expensive the raw material and the more tight the delivery schedule, the more important it is to get parts first-time-right. While our first-level tool management practices focus on saving time with predictive tool setups, the second level focuses on time and material savings generated through ensuring consistent quality (by mastering the tool offsets).

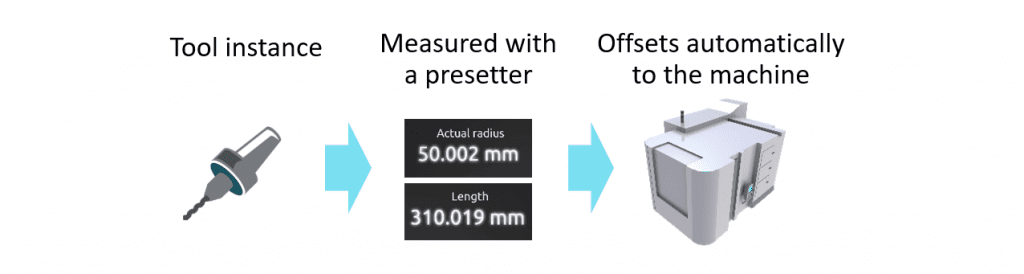

First, you need a tool presetting device for fast and precise cutting tool measurement. Tool presetting allows for the precise tool measurements and position to be input to the machine tool. This saves time in test runs and allows for tool setups to be done beforehand. Secondly, you need the tool presetting device integrated with your production system. This allows for tool offsets to be automatically transferred to the machine tool control – to run the batches precisely and right after the previous one has been finished. This also frees the operator’s time for more productive work.

With an integrated tool presetting device, the cutting tool presetting errors are removed and there will be no more scrap or spindle crashes due to wrong offsets. Our next cutting tool related post focuses on the third level of the best tool management practices: how to share tools between machine tools in order to further increase machine tool utilization and simultaneously generate savings in cutting tool and magazine costs. Stay tuned!

Interested in understanding all four levels of the best cutting tool management practices already? Click here. In addition to that, be sure to register for our upcoming virtual seminar. This will be a day for educative webinars, video demonstrations and Q&A sessions on several productivity-related topics, including cutting tool management.