Ingersoll Rand Increased Machining Capacity with Highly Integrated FMS and Cutting Tool Automation

When their offering mix kept increasing and ultimately doubled, Ingersoll Rand faced challenge on how to add production capacity when the machining cycles are relatively short and require a lot of cutting tools. Fastems’ FMS equipped with tool automation saved operators time, increased machine tool spindle utilization and integrated various processes into one.

Ingersoll Rand is a world leading compressor manufacturer that globally employs 21,000 people. In their new production site opened in 2022 in Nokia, Finland, they manufacture oil-flooded screw compressors for various industries. The production mix and volumes vary depending on customers’ needs. Jani Mannila, Advanced Manufacturing Engineering & Production Manager summarizes the key manufacturing needs:

“Our compressors have lifetimes of up to 100,000 hours, which means our quality standards are extremely high. We can produce parts on single-piece flow or in series – and we want to offer reasonable and predictable for our customers.”

“Our production mix has doubled over the past 14 years. Our machining times are relatively low and one operation can require up to 70 cutting tools. Automating only the machining pallets would not give us the flexibility we need.”

Since Ingersoll Rand had been using Fastems flexible manufacturing systems (FMS) for three decades already, they were familiar with how varying production orders can be automatically scheduled and run across different machining centers – achieving high spindle utilization, short lead times and repetitive quality. With the highest ever manufacturing mix, Ingersoll Rand wanted to also minimize tool-related machining waiting times and the constant operator effort to keep the machines fed with enough tools.

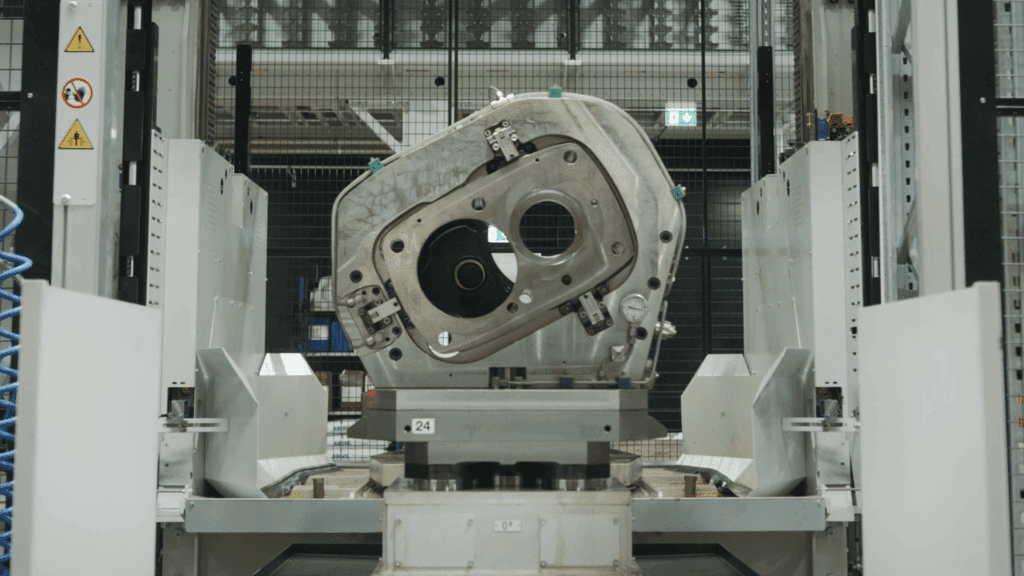

The FMS at Ingersoll Rand’s new site therefore automates not only the machining pallets but also the cutting tools. Fastems’ space saving Gantry Tool Storage (GTS) accommodates almost 1,000 tools above the machining centers, and schedules and shares tools across different machines. Each tool can be maximally utilized and the machines always receive the required tools in time. Once tools are out of life, GTS automatically delivers them for operators into an ergonomic tool station in tool presetting area.

To ensure the highest quality and traceability throughout the manufacturing process, each part is marked and automatically traced with a unique ID. To ensure each part meets strict specifications, machining probe measurements are automatically transferred into a statistical software that helps to track and eliminate possible intolerances.

“The system provides information for our operators on what to do next in order to keep the machining ongoing. This level of automation enables our entire team handle multiple roles, from inbound logistics to CMM,” says Mannila. “Our next step is to introduce part loading automation into machining pallets – this increases productivity further and sets the system up for 24/7 machining.”

FMS at Ingersoll Rand

Fastems Multi-Level System (MLS) at Ingersoll Rand automates:

- 4 horizontal machining centers by DMG Mori

- 64 machining pallets

- Height-adjustable, safe and ergonomic pallet loading stations

- Gantry Tool Storage (GTS) for 994 cutting tools

- AquaClean washing machine

- Coolant and chips in a centralized system

- Part traceability and probe measurement data transfers