When you need more machining capacity, what is your strategy? Adding machines and skilled labor would be the obvious answer. If the latter does not become your limiting factor, the space often does. For today’s manufacturers, floor space is not only a physical constraint but also a strategical resource. Production mixes keep growing but the space doesn’t. How can CNC automation help?

1. Multiplied Spindle Utilization

Flexible automation systems significantly increase spindle utilization, enable lights-out shifts, and reduce setup downtime. This unlocks hidden potential within your existing footprint. In some cases, an automated horizontal machining center can even replace multiple standalone machines. Tool and material handling are streamlined, and setups are done offline, meaning machines are always ready to run.

2. Less Floor Space

Many assume automation needs more space, but often the opposite is true. Multiple machines can be linked and centrally controlled, eliminating the need for wide aisles and individual operator stations. A single central control area is enough. This reduces both space and staffing requirements. Fewer operators per machine means shorter paths, smaller safety zones, and more efficient use of space. Modular automation systems can also be retrofitted into tight production environments — flexibly, incrementally, and brand-independently.

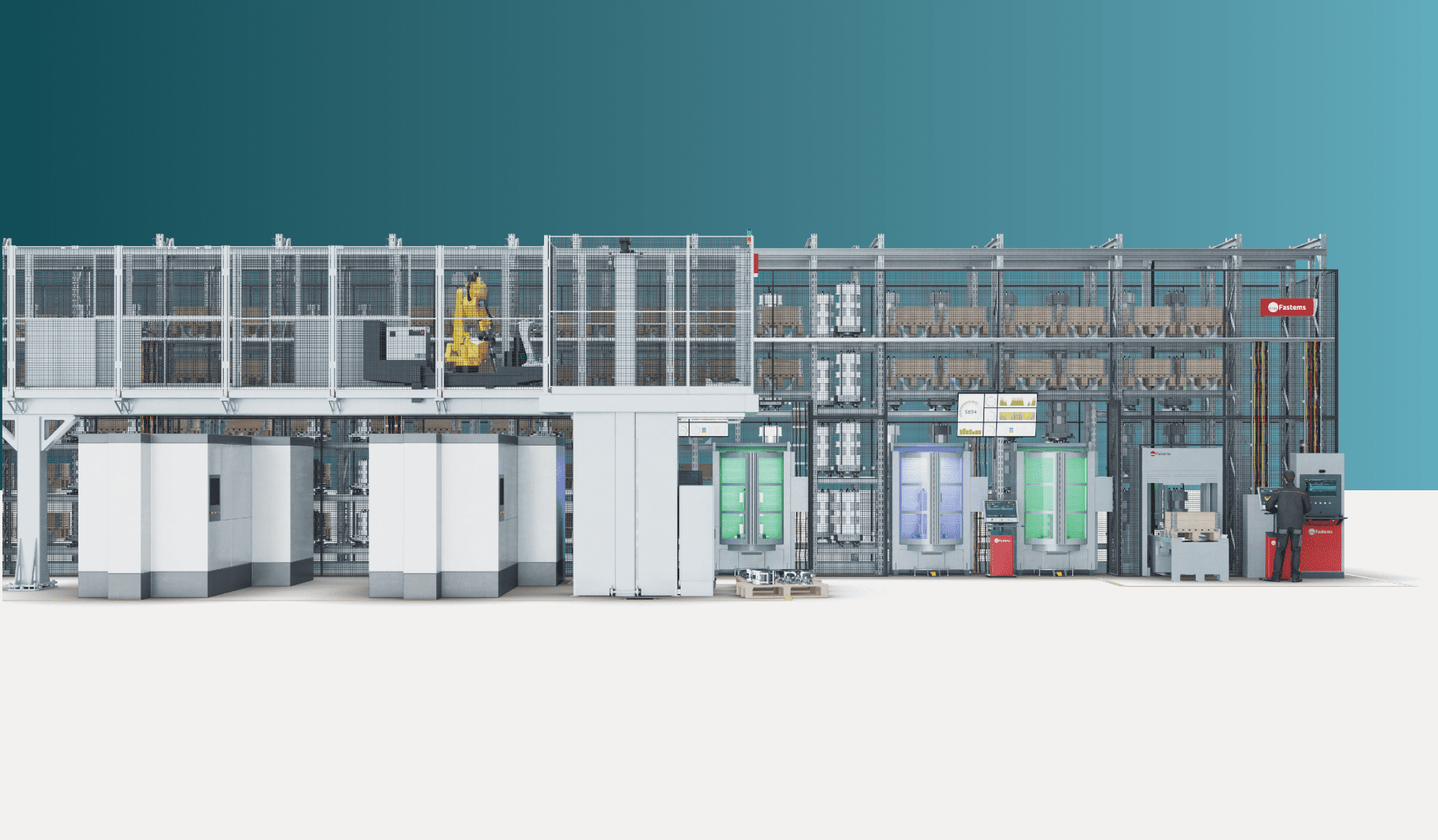

3. Vertical Space Utilization

In high-mix-low-volume environments, vertical space can be a game-changer. Flexible manufacturing systems store machine pallets vertically, making full use of ceiling height to enable high part mix and lights-out capacity. Instead of expanding outward, automation grows upward — an ideal solution when your floor space is limited.

4. Reduced Energy Consumption

Yes, chip cutting consumes energy. But how to keep it as sustainable as possible? Flexible automation maximizes productivity per square meter — this means, you have less space to build and heat, and fewer machines to power up. This is not only an environmental action — it also helps you comply with your customers’ standards and win more business.

5. Adapting to Your Production Environment

Flexible automation system should integrate seamlessly into your existing production environment. In practice, loading stations, pallet storage, and machines could be positioned on any side of the system, tailored to your layout. Ideally, the system is compatible with various machine brands, allowing you to automate existing equipment without major redesigns. This ensures future-proofing without the need for a complete overhaul.

Automated CNC machining doesn’t just make better use of your machines — it makes better use of your space. And in manufacturing, that’s a competitive edge you can measure in both meters and margins!

Are you joining EMO in Hanover 2025?

Visit us from September 22–26 in Hall 12, Booth B54 to explore Flexible Pallet System (FPS) — a modular, space-saving automation solution compatible with hundreds of 4- and 5-axis machining centers from various manufacturers. Try our new FPS Studio on-site and configure a system tailored to your machines and floor plan.

Want a free ticket? We have it ready for you — just click the button and join us!

To read more about Fastems’ Automate Machining and More showcase, check our event page.