Do you know how many work cells you have on your machining shop floor? What are all the production resources you need to run your shop – and how do you plan everything together? Does your team know where everything is and what the most important job to run next is?

Most machine shops use pen and paper or an Excel sheet to plan and manage floor-level operations. The typical result? Lack of transparency, poor capacity utilization, and lost profit – especially when it comes to manufacturing with a variety of stand-alone machines, production cells, and manual operation phases.

The ability to control the whole production process from order to delivery is what MES (manufacturing execution software) solutions are built for. In this post, we present the five key MES features that minimize production hassle and maximize the output and profitability of YOUR machine shop.

1. Up-to-Date Production Data in a Single Source

MES saves and maintains your production data – part master data, work instructions, quality documentation, storage locations, and much more – centrally. It is a single tool for your whole team to access anywhere they need. You can rest assured everyone uses the same, up-to-date version of your data – all the time.

2. Real-Time Production Scheduling

To ensure timely orders and production efficiency in complex and changing circumstances, MES offers you real-time production scheduling that considers both your production orders with their due dates and your available production resources. It calculates the optimal route for each order, ensuring every order is ready on time and your production resources are maximally utilized. Your team has full visibility on what’s about to happen next and the following days.

3. Intelligent Resource Management

MES keeps your team informed on which production resources – such as cutting tools, NC-programs, raw materials, and work setups – are missing from the upcoming orders. You know exactly what to prepare by when, and you can also plan your work in advance. With intelligent resource management, your work cells and machines are prepared beforehand for the coming tasks – reducing the overall idle and waiting times.

4. Material Logistics Management

The more stand-alone operations and separate cells you have in your process, the more manual transfers are required. MES offers your operators an automatic transfer task list for both internal and external logistics – ensuring that the transfers cause very minimal delays in the process chain. What this also helps is removing unnecessary work-in-process from your shop floor – reducing tied capital.

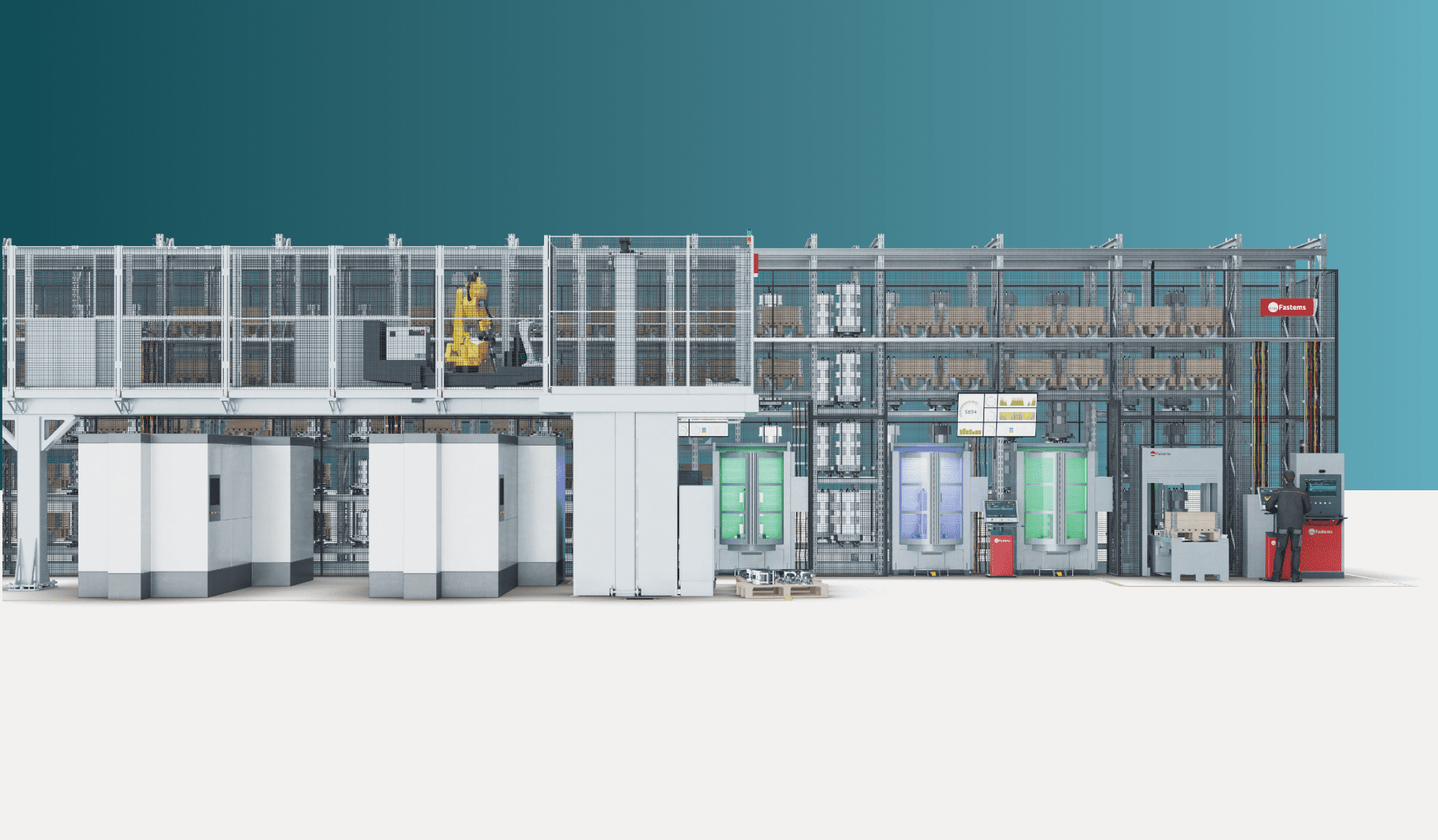

5. Integrates with CNC Automation

You can use MES as a stand-alone solution. But if you have automated part of your process, why not integrate all under the same production planning? MES can include your automated production, stand-alone machines, and manual operations – all under the same production scheduling. This allows you to gradually improve your productivity and always take the most out of your current setup, no matter what it consists of.

Seamless Operations Across the Board

MES offers you less stress and chaos, thanks to smart production planning and clear task assignments. Everyone knows what to do, and all required resources—raw materials, tools, NC programs—are at the machines right when they’re needed. The outcome? Increased productivity through better capacity utilization, intelligent planning and guidance, reduced work in progress (WIP), and better delivery performance.

Attending EMO in Hanover 2025?

Come visit Fastems in Hall 12, Booth B54 where we will demonstrate how Fastems MES solution Work Cell Operations (WCO) can integrate your stand-alone machines and manual workflows under one production planning – with or without Fastems FMS.

Try WCO for Free and See the Difference

Get a free 3-month WCO license – including also installation and training for your team. Place your order during August 18 – October via this link or directly at our EMO booth!

Free EMO Day Ticket

We have it ready for you — just click the button and join us!

To read more about Fastems’ Automate Machining and More showcase, check our event page.