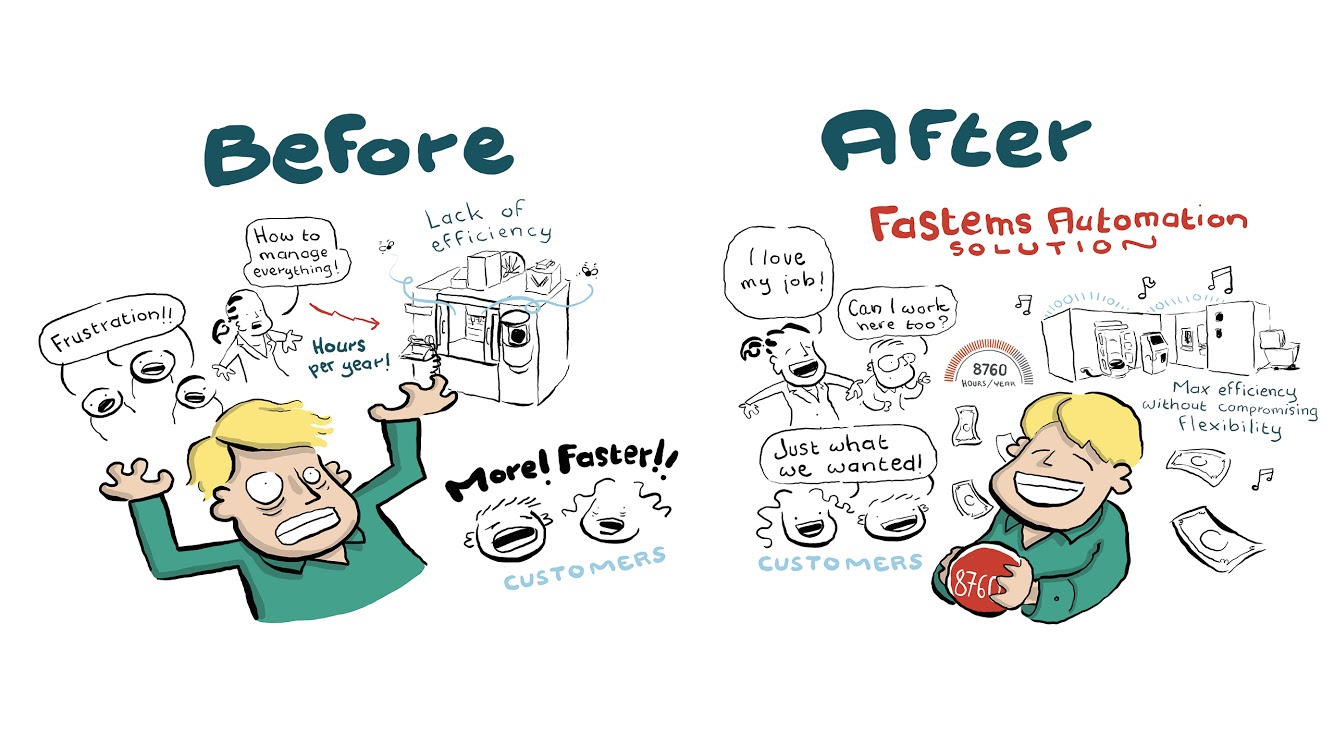

Yet another day starts with a hassle when a few operators happen to be out-of-office, and the production manager needs to find substitutes. Other issues then start piling up on top of that, because new operators are hard to find and even more difficult to keep. At the same time, there are nine 3-axis vertical machining centers on the factory floor, which are causing stress due to limited capacity and standstills. The production manager is getting quite frustrated with the daily hassle, and the customer’s demand for more affordable products isn’t helping the mess.

The production manager gets a chance to discuss production development options but doesn’t get excited straightaway. There isn’t enough time to really think about the possible development changes, and eventually, the topic is dropped. After all, the manager’s hands are full with human resources management work, as well as production issues with the current machinery.

When frustrated enough, the production manager finds time to give it more thought. At the same time, an interesting presentation about “automation being easy” and an offer come in, claiming that a 4-axis machining center with a pallet changer and a pallet system would provide more efficient production capacity and less human resources issues. After some number crunching and serious discussions with the supplier, the manager and company decide to take a leap of faith.

The investment starts to pay off immediately after the ramp-up. The production manager understands that the solution to getting better profits is increased production capacity, and receives a permit to reinvest in a pallet system extension and another 4-axis machine tool. The outcome is unimaginable.

Thanks to automation, the production capacity for two 4-axis centers is better than what it was with the original machinery setup of nine verticals. Furthermore, the operators can work with better ergonomics in loading/unloading and benefit from today’s touch-screen user interface of the automation solution – the kind of work for which it is easier to find employees. What’s best is that the company can respond to the market’s need for high mix and low volume production with a competitive but profitable price-level.

This story is based on multiple cases our partners and we have seen. Automation is easy, and it can bring you significant returns if you give it a chance. At Fastems, the simplest solution can be our MMS + Flexible Pallet Container (FPC) + machining center with a pallet changer. The core of it all is to re-think the whole production process and future demands.