Revolutionize Your 4 or 5 Axis Machining

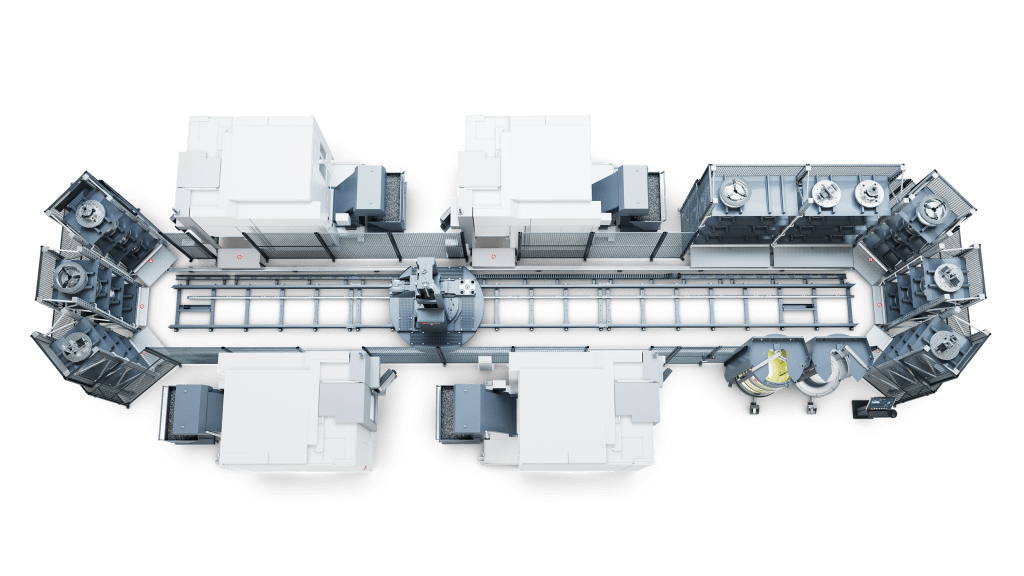

with the NEW 360° Flexible Pallet System – FPS

FOR ANY 4 OR 5 AXIS MILLING OR MILL-TURN MACHINE TOOL

Modular Automation for Milling Machines

Flexible Pallet System (FPS) enables lights-out manufacturing and high spindle utilization in high-mix production with 4 and 5 axis milling and mill-turn machines, also with compact vertical 5-axis machines.

-

Long-reach pallet manipulator – integrates with both APC and directly loaded machines

-

Two size versions – perfect for 300-630 mm pallets or zero-point plates

-

Select your machine tool – FPS integrates with 90+ machine tool brands

360° FIT FOR SHORT, NARROW AND LOW-CEILING FACILITIES

Place Your Machines and Pallet Storage Freely

360-degree layout allows placing your CNCs, configurable pallet storage modules and operator work stations in any four sides of the system.

-

Height-configurable storage modules – maximum storage density

-

Both side and end-of-system storage – utilize all your space

-

The system height only 3.1-4.1 meters (122-161″) – fits in low-ceiling facilities

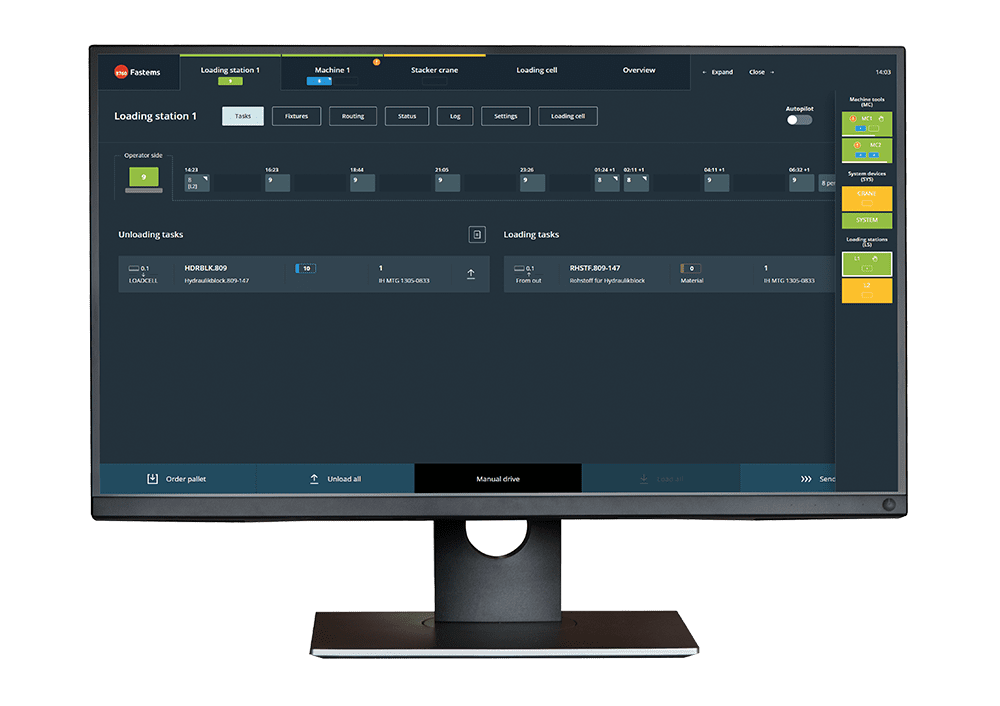

EASY NEW PART INTRODUCTION & RE-RUN OF RECURRING PRODUCTION JOBS

Produce High Mix Efficiently

MMS, the control software of FPS, is designed specifically for high-mix manufacturing needs. It is a tool for everyone working in production or managing it, giving a real-time view on what happens in production and most importantly, identifying exactly what needs to be done next to ensure timely deliveries and maximum spindle utilization.

-

Automatic & adaptive production scheduling based on customer orders

-

In-advance production resource check & operator instructions for each job

-

Situational awareness – know exactly what happens right now & within the next 96 hours

-

Introduce new parts into production fast – once you save part data in MMS, you can re-run the job any time

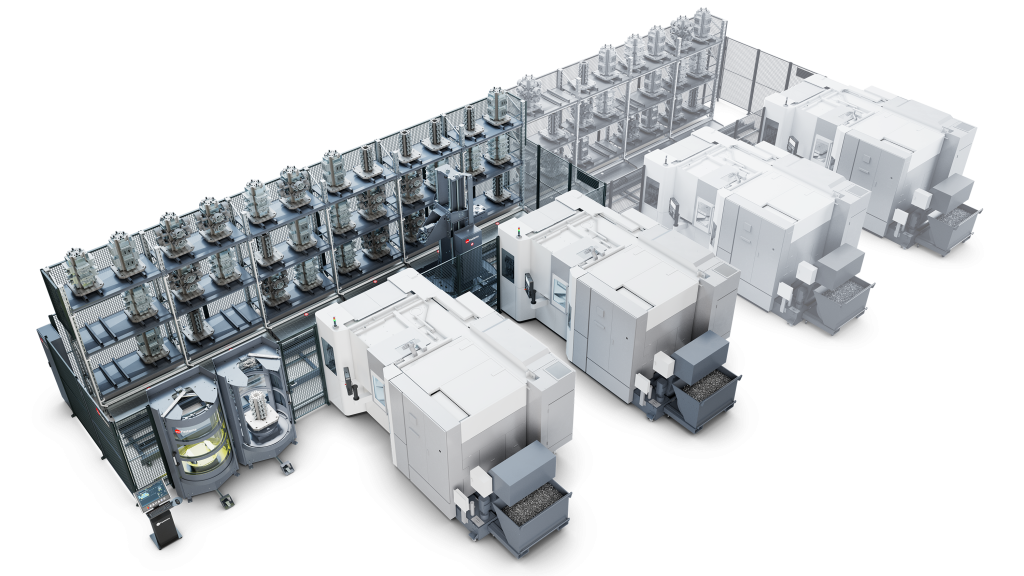

ADD MORE MACHINES AND STORAGE WHEN YOU HAVE NEW PRODUCTION NEEDS

Extend Your System Later

The system can be extended later when the production needs change. You can add more machine tools, more storage capacity – upgrade it with new software features, or relocate your system for instance.

-

Extandable system for more machine tools and storage places

-

Software upgrade package offers you new features when manufacturing technologies develop

-

You can modernize or re-locate your physical system to make it last for decades

Product Details

Learn the product features, download the brochure and see the technical specs!

READ MORE ABOUT FLEXIBLE PALLET SYSTEM

Automation Webinar 12th Oct 2023 at 9 AM CET or 11 AM EDT

Reserve your seat and learn how to automate 4 and 5 axis milling and mill-turn machine tools for flexible and efficient high-mix production!

RESERVE YOUR LIVE WEBINAR SEAT

Want to Talk with an Automation Specialist?

Fill in the form and we will be in touch.

"*" indicates required fields