System Updates

For Extended Lifetime

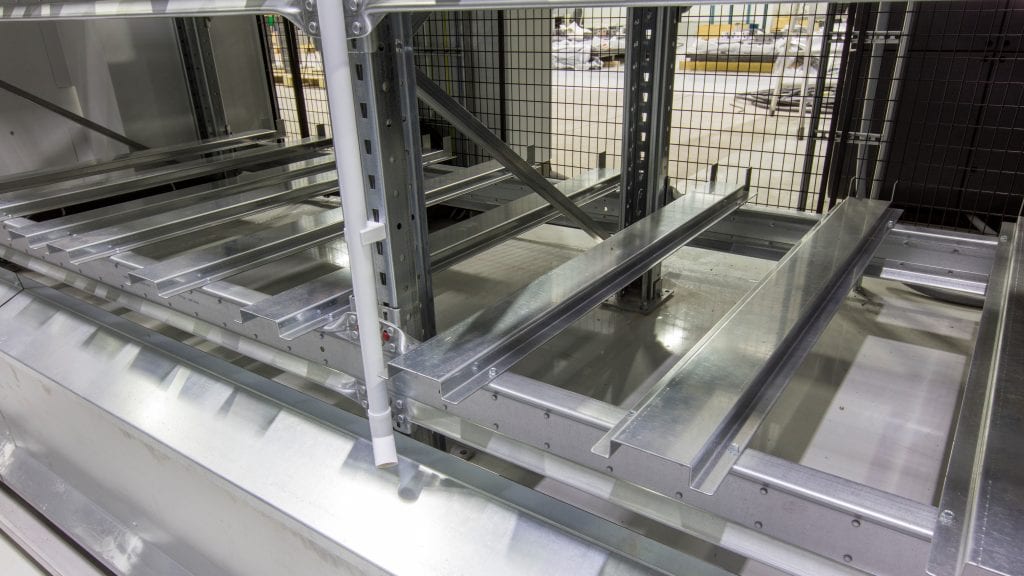

Extensions

All Fastems pallet and tool automation products are extendable by nature because of their modular structure.

Read More

Modernization

Our modernizations range from simple software updates to productized upgrade packages or even full scale automation hardware rebuilds with the latest technology.

Read more

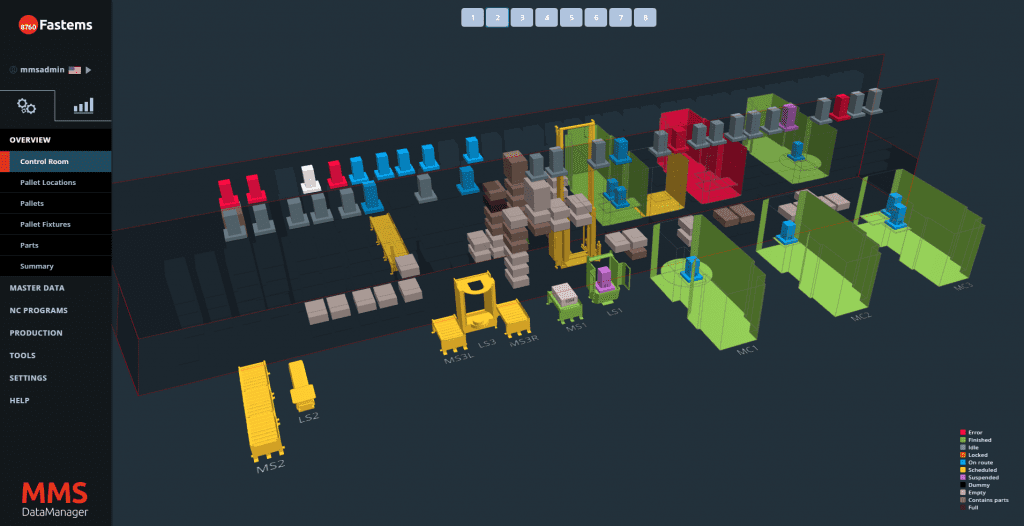

Software Maintenance

Software is an essential part of the modern manufacturing environment, which means it needs to be maintained. The continuous development of MMS regularly brings new features, improvements and fixes.

Read more"*" indicates required fields