[Tampere, Finland – November 2020] Now, even higher payload machine tools that do not feature automatic pallet changers can be configured into an FMS (Flexible Manufacturing System) via a new, multi-pallet loader from Fastems that accommodates payloads up to 1,000kg.

Fastems, one of the world’s leaders in manufacturing automation equipment and software, has developed a new load handler that can both load machine tools directly and act as an automatic pallet changer. The load handler is the device on the FMS stacker crane that moves pallets between storage, machines, and the loading/material stations in a Fastems FMS. Fastems calls this new loader DMC-APC, which means Double Mast Crane-Automatic Pallet Changer. Using the new DMC-APC, manufacturers do not need to purchase and integrate costly APCs to their machine tools in order to configure an FMS in their facilities.

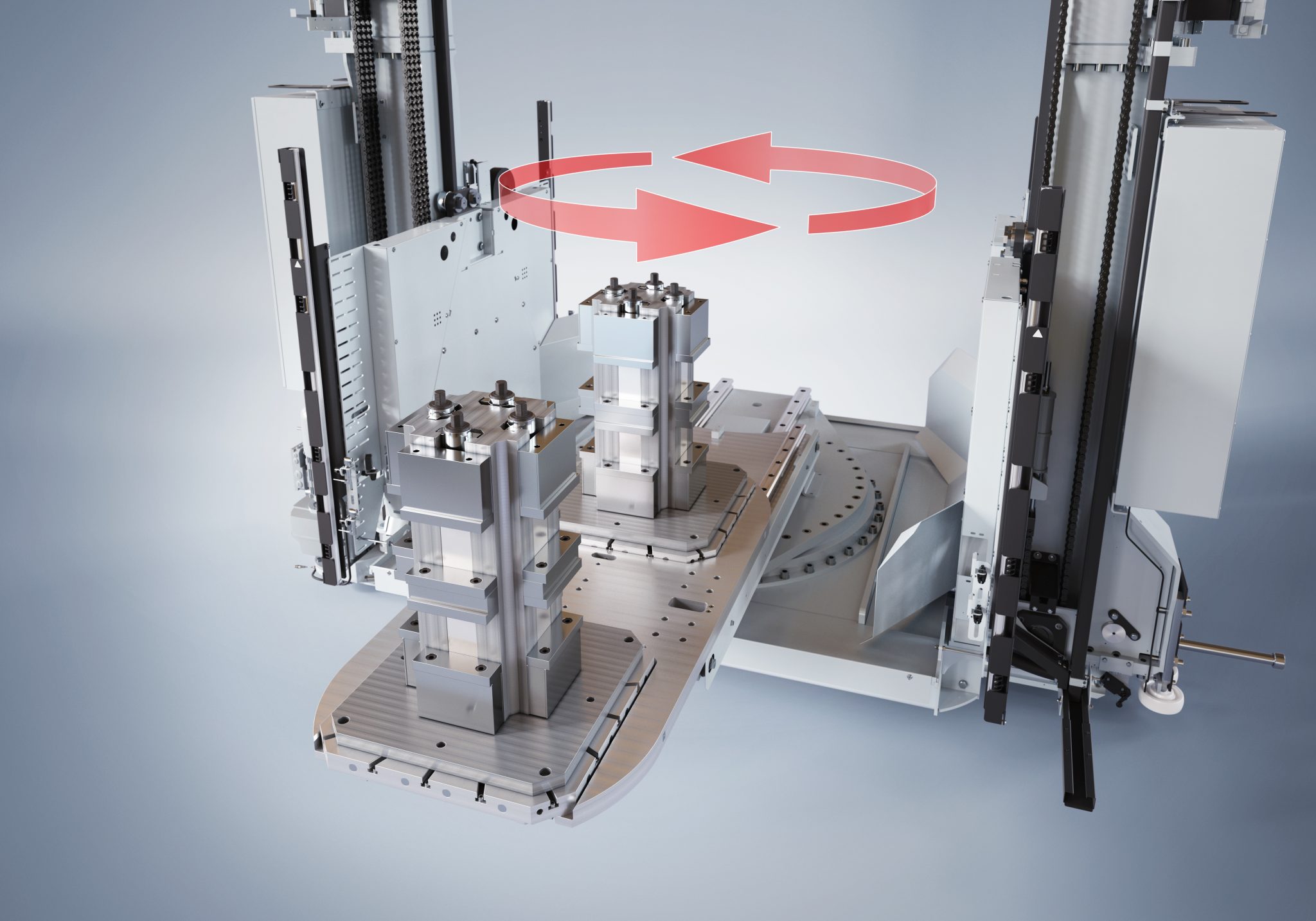

In operation, the new Fastems DMC-APC can accommodate two pallets rather than the typical single pallet. Controlled by the Fastems cell management software, the DMC-APC selects the next workpiece-loaded pallet from the storage system, moves it to an open machine tool, then picks up the previously machined workpiece/pallet from that same machine tool, spins 180-degrees, and places the new workpiece/pallet into the same machine tool. This scenario takes about 30-40 seconds. In comparison the cases where the non DMC-APC or classic stacker crane accommodates one pallet instead of two the loader first takes the finished part/pallet from the machine tool, delivers it to the storage stacker, moves to pick up the next workpiece/pallet to be machined, and delivers it to the machine tool ready for machining. This scenario with one pallet takes about 100-120 seconds.

According to Fastems, there are several notable benefits now that non-APC machine tools with higher payloads can be used in an FMS, namely surrounding speed, machine tool utilization, and cost reduction. For instance, if the machining cycles are short, the necessity to make several pallet changes within one hour decreases machine tool utilization significantly. Second, with the DMC-APC’s double pallet capability, the pallet change time is about half a minute compared to two minutes with a single pallet changer. Third, the DMC-APC saves floor space because machines without APCs have a smaller footprint generally. Fourth, customers do not have to invest in machine tool APCs which can cost up to $100,000 each. Fifth, the new generation DMC-APC can accommodate higher weights up to 1,000kg.

For more information, visit www.fastems.com, or contact Marketing Manager Sarianne Niemi, sarianne.niemi@fastems.com, m. +358 50 520 3183.