EMO 2025

Hanover, GermanyBE EFFICIENT. BE FLEXIBLE. BE SCALABLE.

Automate Machining and More

EMO Hannover is the flagship gathering for the global metalworking community, where the focus is on precision, efficiency, and increasingly connected manufacturing. From September 22–26 in 2025, you’ll find Fastems in Hall 12, Booth B54, where we demonstrate how flexible CNC manufacturing can take you further – not only automating machining, but your whole operation chain – not only moving parts from A to B but using software to intelligently plan, manage and developing your order-driven manufacturing.

Experience the Future of Machining!

Visit us and discover how to transfer your machining and surrounding operations into an efficient, flexible and automated workflow. Fastems modular CNC automation solutions integrate seamlessly with over 90 machine tool, device and data system brands of your choice. Our digital offering delivers transparency and intelligence across all your workflows, no matter if your operations are automated, manual or stand-alone.

In EMO you can meet our automation specialist team and get answers to your questions regarding flexible manufacturing, machining, fixturing, cutting tools, integrations, and anything around CNC automation!

SEE LIVE SYSTEMS & SOFTWARE

Show Highlights

SHOWCASE HIGHLIGHT

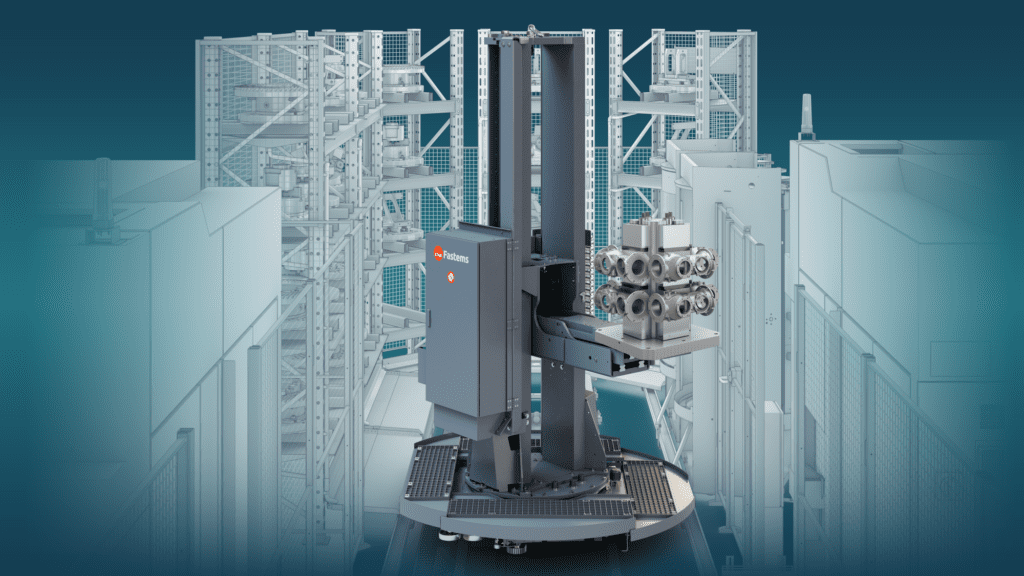

Flexible Pallet System (FPS)

FPS automates 4 and 5 axis horizontal and vertical milling machine tools for payloads from 500 to 1,500 kg. It is a space-saving, modular, and compatible with a wide range of machines.

- Increases machine tool spindle hours by delivering ready-loaded pallets

- Modular and compact 360° layout is ideal for tight shopfloor

- Scales with more machine tools when your needs grow

- Compatible with machines from over 90 manufacturers

Try out our new FPS configurator at the booth to see what setup fits your production the best!

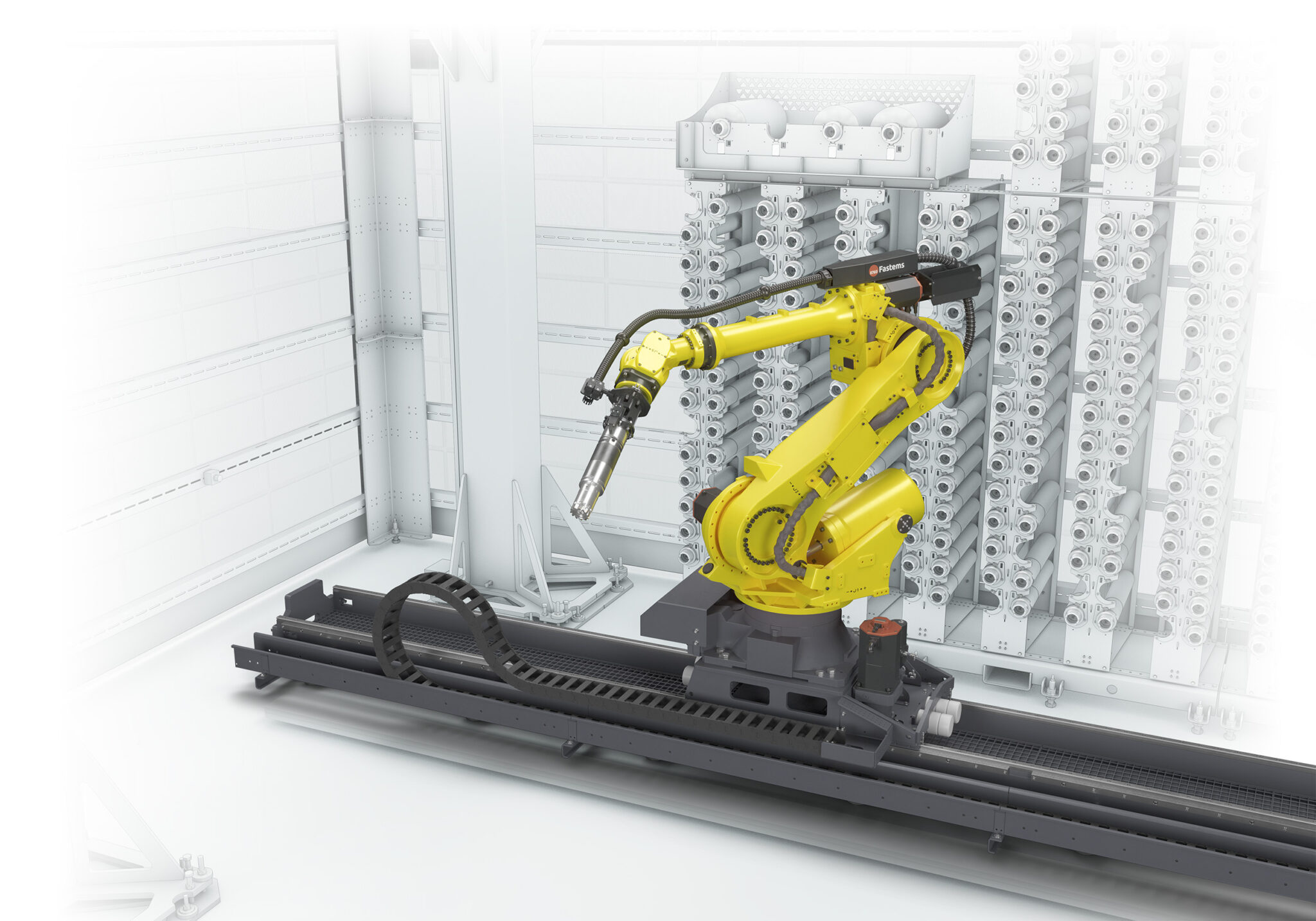

POWER UP TOOL PROCESSES

Cutting Tool Automation

When your tool demand is high, tool loading can form a bottleneck for machining. Our tool automation solutions Gantry Tool Storage (GTS) and Central Tool Storage (CTS) help to save operators’ time from changing tools, and enable:

- Longer lights-out machining

- Efficient tool sharing between machines

- Reduced need for large magazines and sister tools

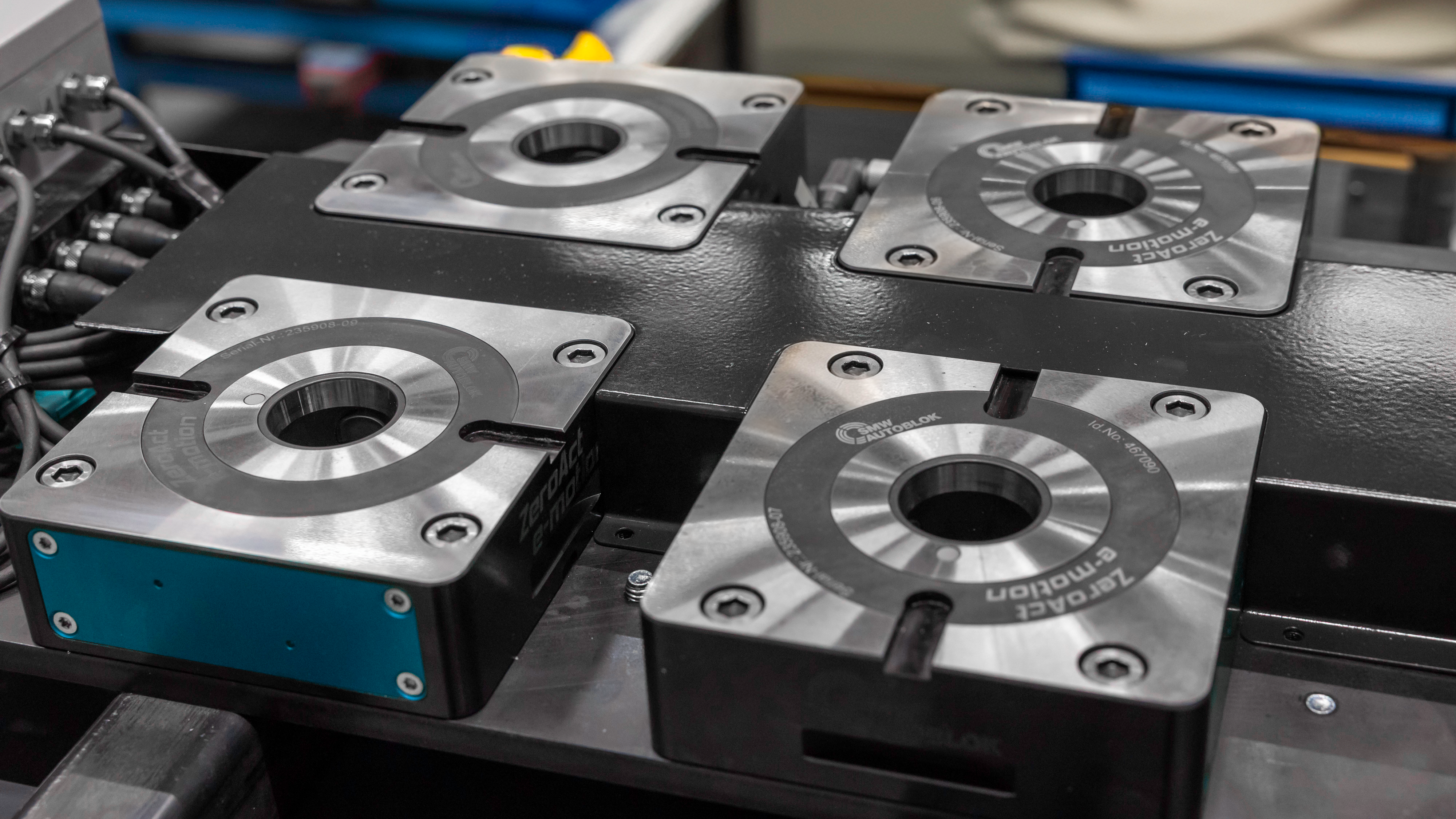

AUTOMATE SINGLE-TABLE MACHINES

NEW eLock Pallet Changing Interface

eLock is a new concept enabling cost-efficient pallet automation for single-table machining centers. Based on electromagnetic power transmission, eLock is a patent-pending, bolt-on zero-point pallet solution.

- Automate new and existing machine tools without leading media or wiring through the machine tool table.

- Integrate various different machine tool types into your pallet automation system.

Come and see the live eLock prototype at our booth!

AUTOMATION SOFTWARE

Manufacturing Management Software

MMS is the control of all Fastems automation systems – designed to plan, run, and monitor high-mix, low-volume production environments.

- Centralized planning and control of all production processes

- Real-time transparency across the entire shopfloor

- Support for both automated and manual workflows

- Optimized scheduling for improved delivery reliability

- Scalable to grow with your production needs

DIGITALIZING MANUAL PROCESSES

MMS – WCO

(Work Cell Operation)

Many steps in manufacturing,

like sawing, washing or packaging, still run without any system connection, and are managed manually with Excel sheets and papers.

WCO allows you to

go paperless and manage these operations digitally –

reducing idle time, manual work, and unnecessary work-in-progress:

- Paperless production for non-automated operations

- Effective digital planning with fewer delays

- Smoother flow between automated and non-automated areas

DIGITAL SERVICE FOR AUTOMATION

myFastems

myFastems offers

digital tools and services that support and enhance the performance of all Fastems systems with MMS (version 6 and above).

With myFastems, users get 24/7 access to real-time insights on system status and performance –

anytime, anywhere:

- Full visibility into system performance

- Faster troubleshooting and support

- Lifecycle support from installation to optimization

- Secure access for all relevant users

for FASTEMS fms customers

Productivity Lab – Reserve Your Free FMS Productivity Assessment

Are you already using Fastems FMS? In our Productivity Lab at EMO, Fastems Performance Team is ready to sit down with you, offer you hot or cold beverages and go through a productivity assessment report we have collected from your system data.

Together, we’ll look at where the current productivity bottlenecks lie, improve transparency across your entire workshop, and identify the best next steps for you to take the most out of your system. The assessment is completely free of charge but the seats are limited – reserve yours now!

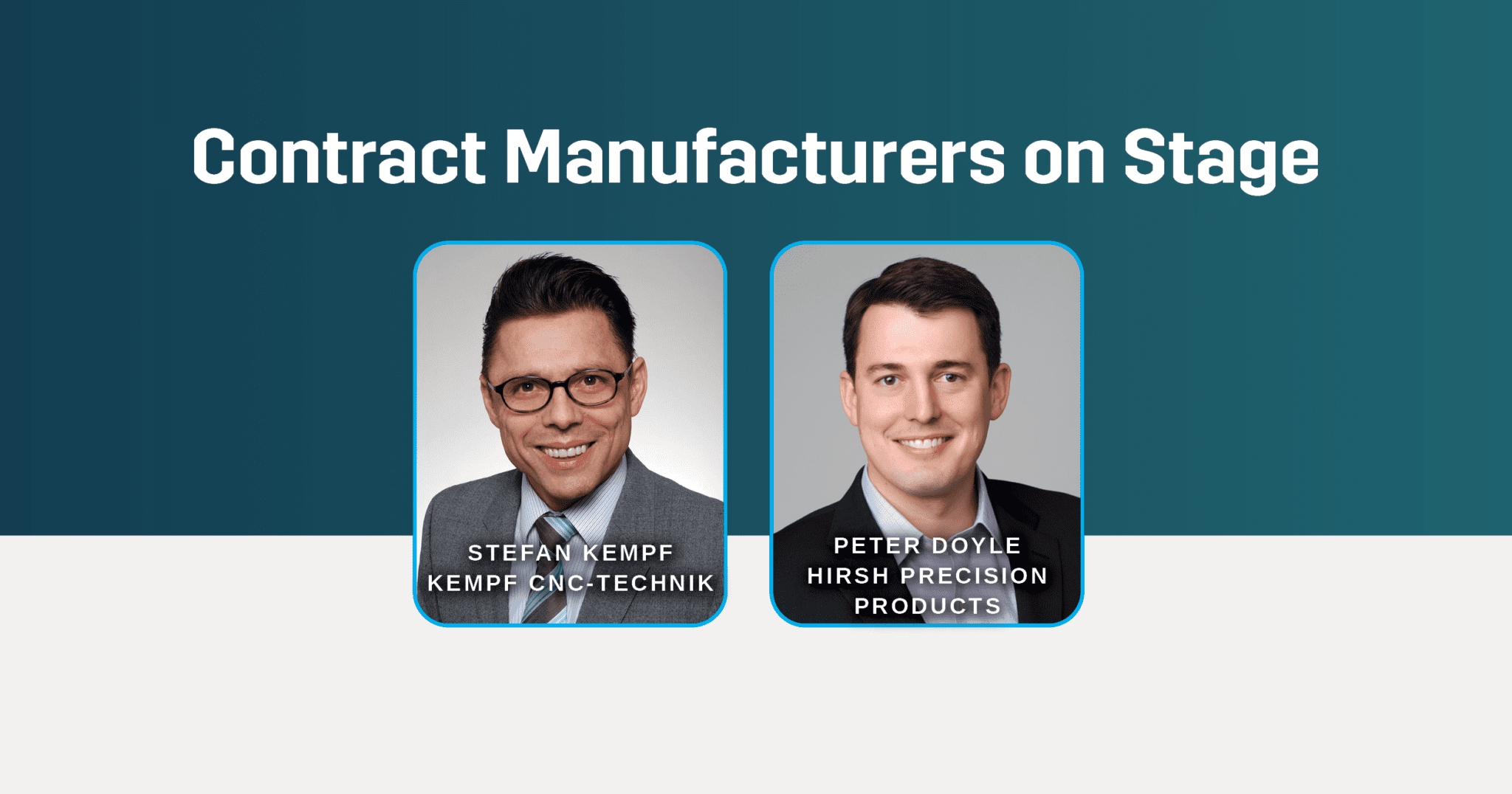

LEARN TO AUTOMATE | WED 24th at 11:00

FMS as Competitive Strategy – Manufacturers on Stage

The days on a machining shop floor are often chaotic – especially when it comes to businesses with constantly changing customer demand.

On Wednesday 24th Sep at 11:00-11:30, two subcontractor company entrepreneurs step onto the EMO Innovation Stage (hall 12, A60), and share their experiences on how to take control of varying shop floor operations and start mastering flexible manufacturing.

After the presentation, you can meet these entrepreneurs for Q&A at Fastems booth nearby (booth B54, hall 12).

Book a Meeting With Our Experts

Are you interested to learn about automation possibilities for your milling, turning or grinding machining processes?

Book a time to talk with one of our experts at the booth and get personalized insights into what’s possible in your shopfloor setup.

Get Your Free Ticket to

EMO 2025

Would you like to visit EMO 2025 in Hanover?

We’re happy to provide you with a free ticket for the full week. Simply request your code below – we’ll see you in EMO!