EMO Hannover 2023

Hannover, GermanyTake the Most Out of Your EMO Visit –

Rethink Your CNC Manufacturing

From September 18 to 23, 2023, EMO in Hanover will once again be the meeting place for experts in the metal cutting industries. Make the most of your visit and stop by Fastems booth D67 in hall 12! Our automation experts are there to help you solve your productivity challenges related to production planning & data, milling and turning machining, cutting tool management or part finishing.

Experience:

- Fastems Auto-LoadingCell (ALD) for Flexible Manufacturing Systems (FMS)

- Flexible Pallet Tower (FPT) and Flexible pallet System (FPS) for milling machines with and without APC

- The new features of our intelligent automation software MMS

- Our digital services that create additional value for your production.

Our Highlights

4 AND 5 AXIS MILLING

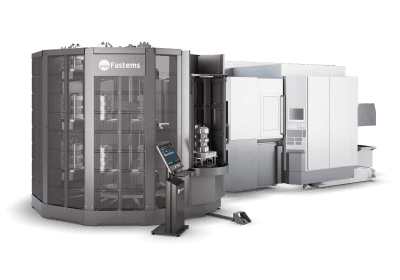

Flexible Pallet Tower

Flexible Pallet Tower (FPT) is the most compact single-machine automation for 4 and 5 axis milling machines with or without automatic pallet changers – also for machines with only one access door. Capable of handling 12 to 24 pallets or zero-point plates of 300-630 mm, FPT is factory tested and fast to deploy automation solution that enables lights-out machining and high spindle utilization. At our booth you will see the live system for 1,000 kg payloads!

Flexible Pallet Tower (FPT) is the most compact single-machine automation for 4 and 5 axis milling machines with or without automatic pallet changers – also for machines with only one access door. Capable of handling 12 to 24 pallets or zero-point plates of 300-630 mm, FPT is factory tested and fast to deploy automation solution that enables lights-out machining and high spindle utilization. At our booth you will see the live system for 1,000 kg payloads!

4 AND 5 AXIS MILLING

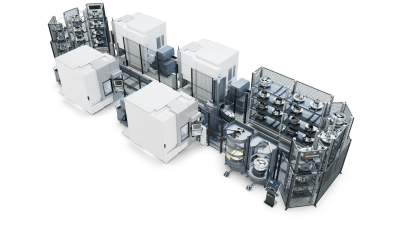

Flexible Pallet System

Flexible Pallet System (FPS) is a brand new compact and modular multi-machine automation system for 4 and 5 axis milling centers and mill-turns. The 360-degree design allows machines, pallet storage, and loading stations to be flexibly placed on all four sides of the system. Like it’s sister product FPT, FPS can handle pallets and zero-point plates from 300 to 630 mm. FPS enables full capacity utilization, lights-out machining and resource sharing for multiple CNCs – and an option to add more machines later on.

FMS PART CLAMPING

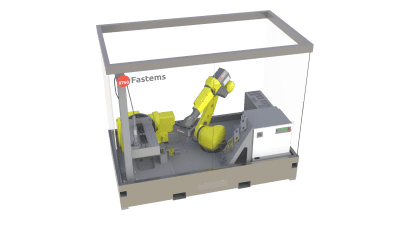

Auto-Loading Cell

The Auto-Loading Cell (ALD) ensures that Fastems FMS runs unmanned around the clock – even when the pallet demand is extremely high. The robot cell loads and unloads the parts to and from the pallets automatically – as well as re-clamps parts between machining operations. Fastems live robot showcase in EMO demonstrates the principles of auto-loading functionality, including clamping the part in different operations, into conventional clamping fixtures that are more affordable option compared to hydraulic or pneumatic fixtures.

AUTOMATION USER PORTAL

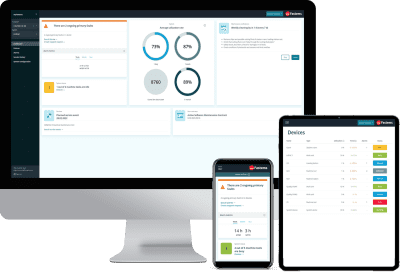

myFastems

Visitors to the Fastems booth will also learn about myFastems. Offered as Software-as-a-Service (SaaS) product, as part of Fastems’ automation solutions, myFastems provides powerful tools to help customers keep their Fastems systems up and running all the time, for maximum availability and productivity. In addition, myFastems also serves as a customer portal, from which its users can easily order spare parts and request support tickets.

PRODUCTION DATA

Factory Cockpit

Factory Cockpit is a solution that collects, integrates and analyzes data from shop floor devices and IT systems (e.g. ERP or MES). The software provides tools for situational awareness and data-informed insights for part manufacturing, which help optimize the overall production flow and resource efficiency. With Factory Cockpit, real-time production statuses or important manufacturing KPIs such as OEE, utilization, and availability, are easily available for all selected stakeholders, both internally and externally.

PLAN, RUN & MONITOR PRODUCTION

Manufacturing Management Software

Manufacturing Management Software (MMS) is designed specifically for high-mix manufacturing needs. It generates production plan based on the production orders, and identifies exactly what needs to be done next to ensure timely deliveries and maximum spindle utilization. Not only does the system consider the pallets that need to be loaded in the machine tools – it also checks and ensures that all the other machining resources (NC programs, cutting tools and raw materials) are there in time.

Come visit us at Hall 12 | D67

Book a meeting with our experts!

You can now book a personal meeting with one of our experts at our booth D67 in hall 12