Lead manufacturing with data.

First, we integrate the existing manufacturing data on one platform.

We create real-time situational awareness of what is really happening in manufacturing.

We turn accumulating data into actionable insights to solve root causes for inefficiencies.

Then, we make information available for everyone involved, including customers and partners.

Finally, we provide means for continuous improvement and optimization.

If you feel that your company has challenges in getting accurate information about operations and performance, you are not alone. Many customers we’ve spoken to say that the inability to leverage and share data prevents them from gaining the visibility and situational awareness they need.

The problem isn’t necessarily the lack of information, but information being siloed into multiple, separate systems that don’t integrate with each other without a lot of work. The same goes for machine data collection. It may also cause its own challenges when combining essential data.

Factory Cockpit is the key to overcoming these silos and gaining a competitive edge. It integrates your existing manufacturing IT systems with your machine and automation systems on the factory floor. It turns the data gained from these assets into valuable information.

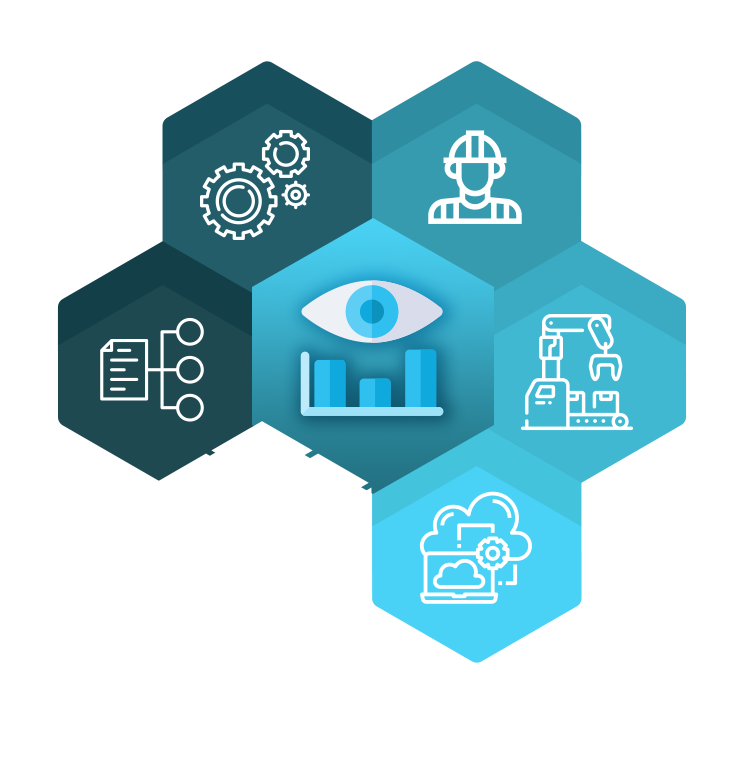

Visualization is the first step in understanding the combined information and transforming it into meaningful insights. Factory Cockpit visualizes your real-time and historical manufacturing data and provides a holistic view of your manufacturing performance.

Advanced production analytics enable bench-marking and real-time visualizations of planned and actual manufacturing flows.This allows you to monitor the actual performance of different resources, departments and the entire manufacturing. You can also drill down to cause-and-effect relationships to find the areas for improvement.

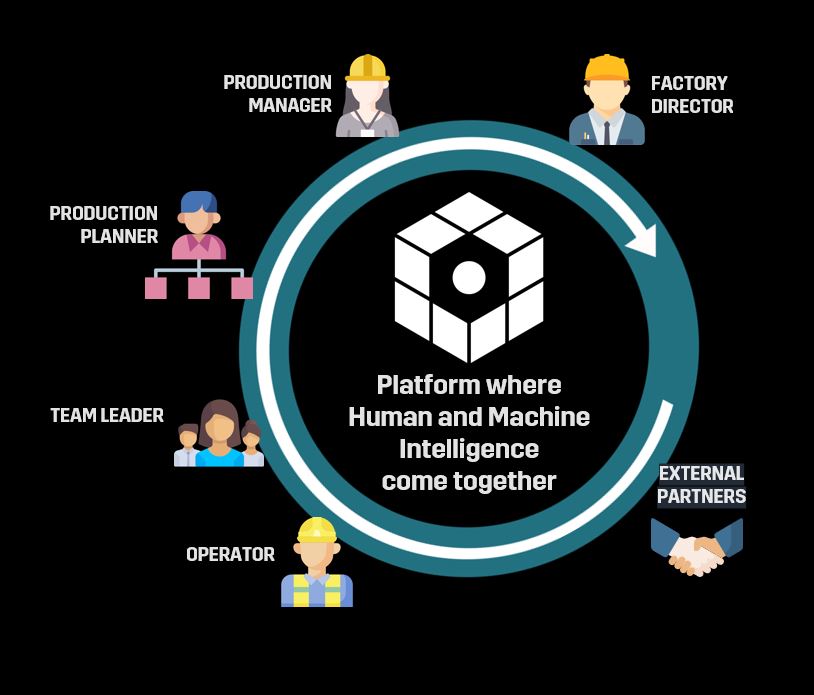

Real-time visualized and analyzed data is changing the nature of decisions in the manufacturing world. Decision-making processes combine the expertise of people and the facts provided by data. This enables faster and more accurate decision-making.

Collaboration and knowledge sharing between stakeholders in production becomes easier than ever with Factory Cockpit. With configurable, user and role-based views, your team knows what is expected, and what their individual hand print is on the success of your manufacturing.

Open APIs and collaboration features allows sharing information also with external stakeholders, thus enables improvements over the whole supply chain. Not only yours, but also your customers’ and partners’ performance capabilities are now advancing continuously.

With the aforementioned data visualizations and analysis, you can effectively find the root causes and fixes for manufacturing bottlenecks and focus on the development activities that have the greatest impact on productivity and profitability. Improved transparency of material flows, traceability information and overall manufacturing status enable performance optimization and increased ROI.

In addition to this, Factory Cockpit stores the collected data on a platform designed for manufacturing in a uniform format, which enables the use of predictive analytics and simulations for further development.