Blog posts, guides, and customer stories on the importance of data utilization in manufacturing.

Our one-pager includes the most comprehensive information about Factory Cockpit.

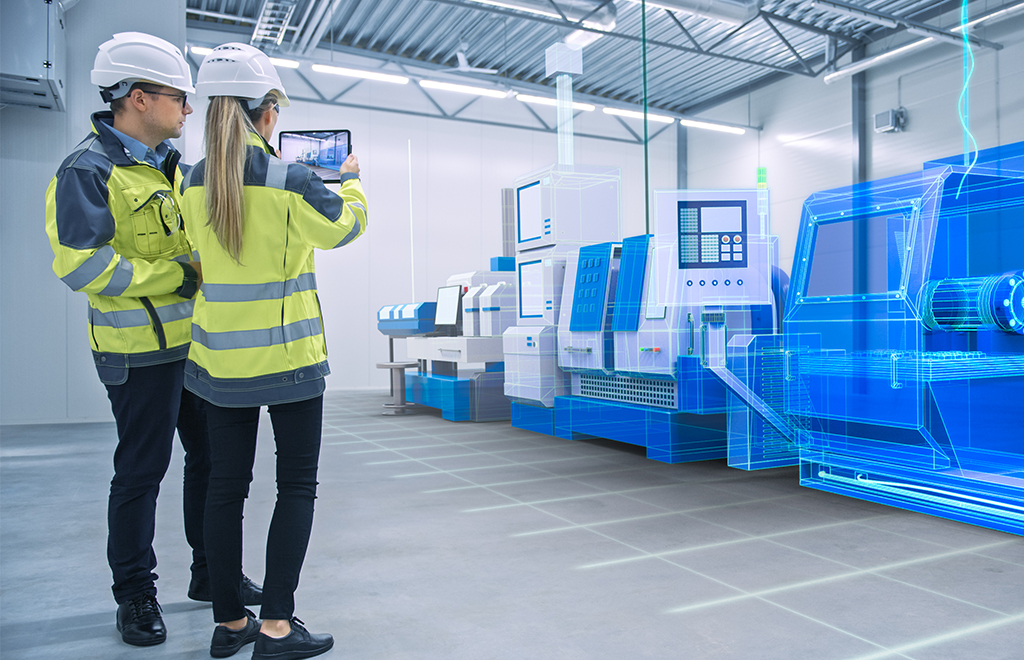

Every manufacturing company has multiple data sources. Whether from shop floor devices, or from IT systems, the data is profound. However, not every manufacturer can utilize the data efficiently. Yet, it is becoming the key to success in part manufacturing. Read the blog post to understand why and how to get started.

Overall Equipment Effectiveness (OEE) is a key metric in monitoring, measuring, and improving the current performance of your manufacturing. However, it is not the most straightforward metric for one to understand and follow correctly. Read the blog to be aware of how to use OEE and what benefits it can bring in the context of part manufacturing.

While not widely addressed within the manufacturing industry, close collaboration among stakeholders is one crucial key to improving efficiency in producitno. Understanding the concept and taking actions towards ecosystem thinking and collaboration, part manufacturers stand high chances of leading the competition in unique ways.

It is no secret that the more timely you are aware about your production, the better you can manage it. This blog post shares our learning from manufacturers about situational awareness. We explore the topic from different perspectives in the shop floor environment: from operators to production and business managers.

Tasowheel, partnered with Fastems to implement Factory Cockpit, a production analytics tool, to enhance transparency and real-time insights on their shop floor. By integrating Factory Cockpit with existing systems, Tasowheel improved decision-making, communication, and efficiency across its operations. This customer story highlights how Factory Cockpit supported Tasowheel’s digital transformation and boosted production performance.

Factory Cockpit is developed in close collaboration between its lead customers and Fastems team. Together, we bring the vision of integrating and utilizing data from shop floor devices and IT systems to life, in the most pragmatic way possible.

Wärtsilä, as part of the OSME (Open Smart Manufacturing Ecosystem) initiative, has taken Factory Cockpit into use.

Giuseppe Saragò – Director of Manufacturing Excellence, Wärtsilä.

Watch the video to learn more about the vision of this collaboration.