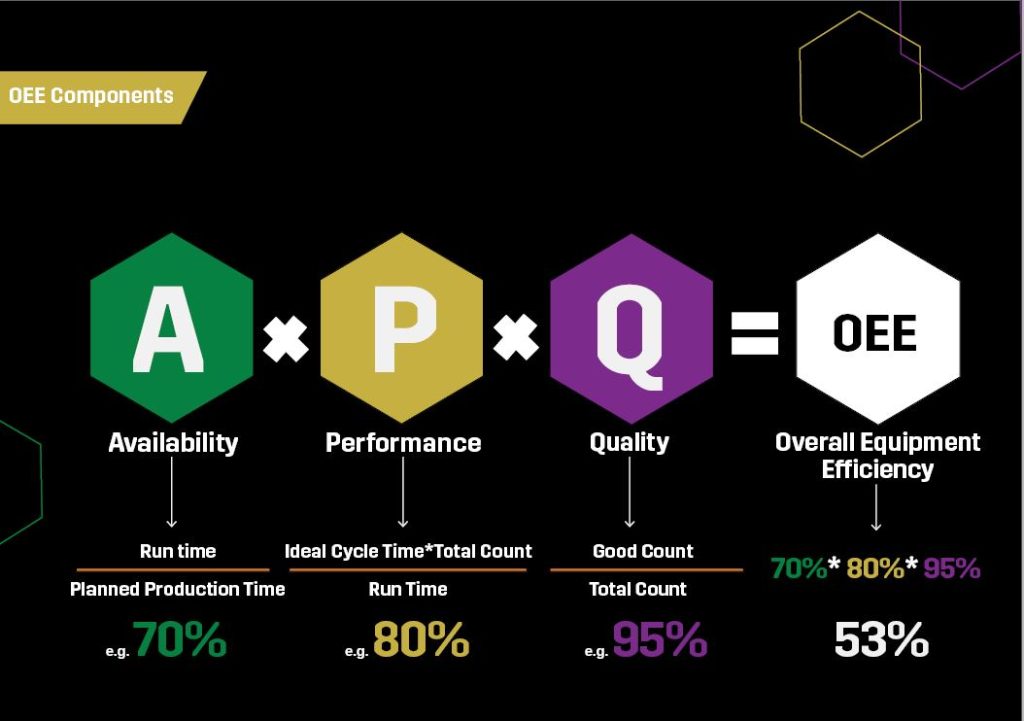

Overall Equipment Effectiveness (OEE) has emerged as a vital metric for manufacturing companies to optimize their production processes and ensure their equipment operates at peak performance. Taking into consideration key performance factors such as availability, performance, and quality, the OEE calculation can help manufacturers identify areas for improvement, minimize downtime, reduce waste, and ultimately enhance their overall productivity.

As simple as it looks, OEE is, in fact, not the most straightforward calculation to make, as there are a lot of variables affecting the components of OEE formula. What defines availability? How to correctly measure equipment performance?

Therefore, we created this guide to answer such questions, help you start with the fundamental values of OEE, how to measure them correctly and how to “decipher” the numbers.

As a manufacturer, you need to stay on top of your production processes to make sure the equipment is running to their full capabilities. By calculating the equipment’s availability, performance, and quality, you will be able to review your existing workflows, detect and eliminate bottlenecks, and reduce downtime and parts rejection rate. All of these actions ultimately result in higher throughput for your manufacturing and sustain the efficiency of our productions.

…considers the planned production time that is available for production. Understanding this component, you will be able to see the actual potential of your equipment, and learn how to utilize them.

… compares the actual running speed of the resource against its specified maximum running speed. This information depicts how efficient your equipment actually is, from which you can detect and minimize bottlenecks.

…takes into account produced parts that do not meet quality standards and need reworking. Having the transparency on accepted/ scrap parts, you can better identify elements that damage your parts and reduce the rejection rate as a whole.

Thank you for your interest in our OEE guide. Please fill in the required information, and we will send the guide to your email right away!

"*" indicates required fields