Factory Cockpit brings together data from your shop floor devices and IT systems and builds comprehensive real-time situational awareness of your part manufacturing. The insights help you to optimize the overall production flow and resource efficiency.

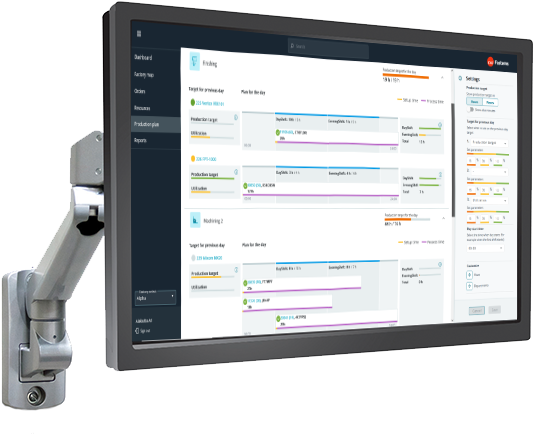

Daily goals and targets are automatically generated for operators on the shop floor. Operators can proactively prepare setups, materials, tools, etc. timely for upcoming jobs. Machine stops can be minimized as resources are prepared and machine tool issues can be attended in a timely manner. Real-time production status tells you where you are in terms of daily goals and makes shift hand-overs efficient.

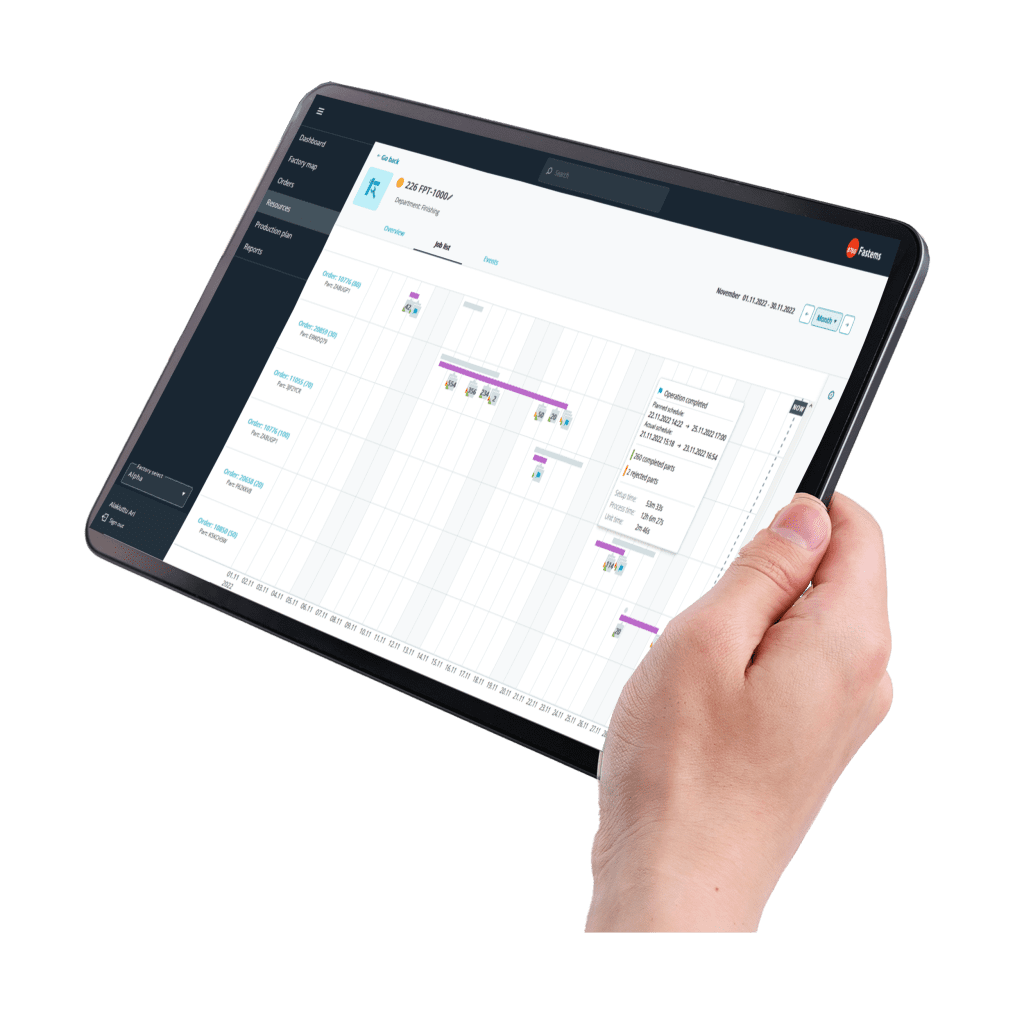

Real-time status for production plan vs. actual progress allows faster and more accurate production planning and goal setting and more efficient daily meetings. Real-time tracking of production orders enables better communication with stakeholders as well as timely reaction to errors and unpredictable events in daily production.

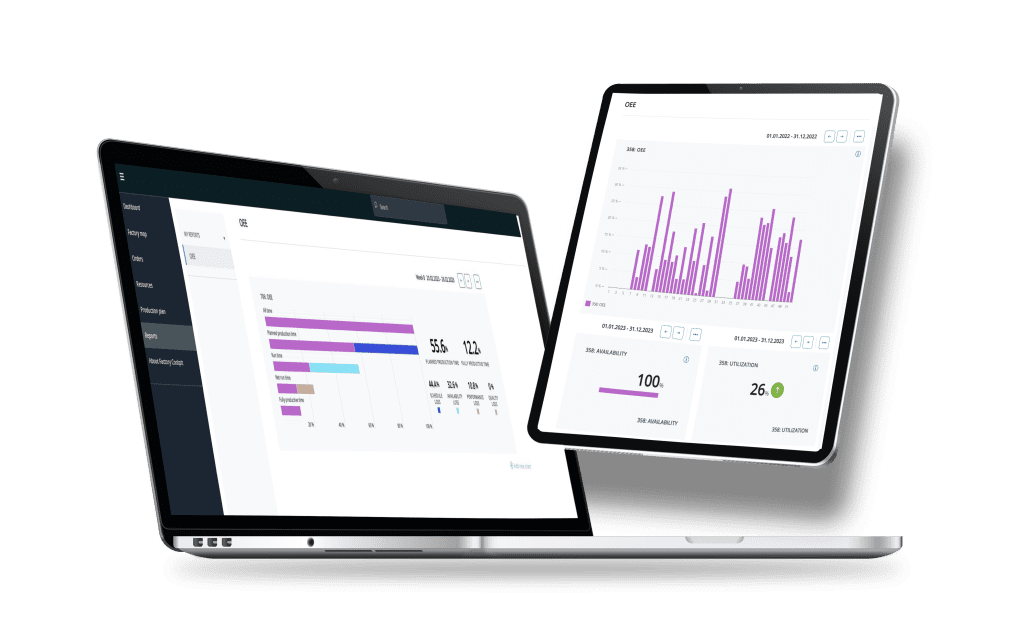

Reports and analysis tools production KPIs, such as lead times, process times, waiting times, and setup times, helps you improving resource utilization, production flow and delivery accuracy. In addition, production efficiency metrics such as OEE, TEEP, MTBF, and MTBR allows you to monitor your production, machine time and shift performance, and the impact of your development activities.

With the overview of shop floor resource and overall production metrics, you can monitor, analyze and lead you production with data. You can set production targets, react to target deviations and validate your decisions efficiently and accurately. With real-time information you can monitor your production and communicate efficiently with your stakeholders.

Factory Cockpit collects and combines your valuable manufacturing data and enables this data to be utilized at different parts of the organization for development actions and improving execution. Your investments and decision-making are backed up with hard facts and numbers, thus making your decisions more reliable.

Instead of data silos, Factory Cockpit allows you to share statuses on production orders, plans, and material flows automatically, both internally and with external partners. Therefore, you can ensure the information is transparent and available for the right people, at the right time, all the time.