In the previous post we discussed Gantry / Central Tool Storage tool automation. This is a system capable of sharing tools from a large, centralized tool storage to different machines, greatly improving machine tool utilization and lights-out times. With CTS, the only thing left up to the operators is tool reworking. But what happens when tool reworking starts to form a bottleneck on the shop floor? Extremely short tool lifetimes combined with a constant and high demand for renewed tools can quickly make tool reworking into a full-time job.

In these cases, tool automation can be extended to optimize the tool setup process as well, allowing for more efficient labor utilization for tool reworking. Let me introduce Tool Service Cell (TSC): Fastems’ latest development for the most advanced tool management needs.

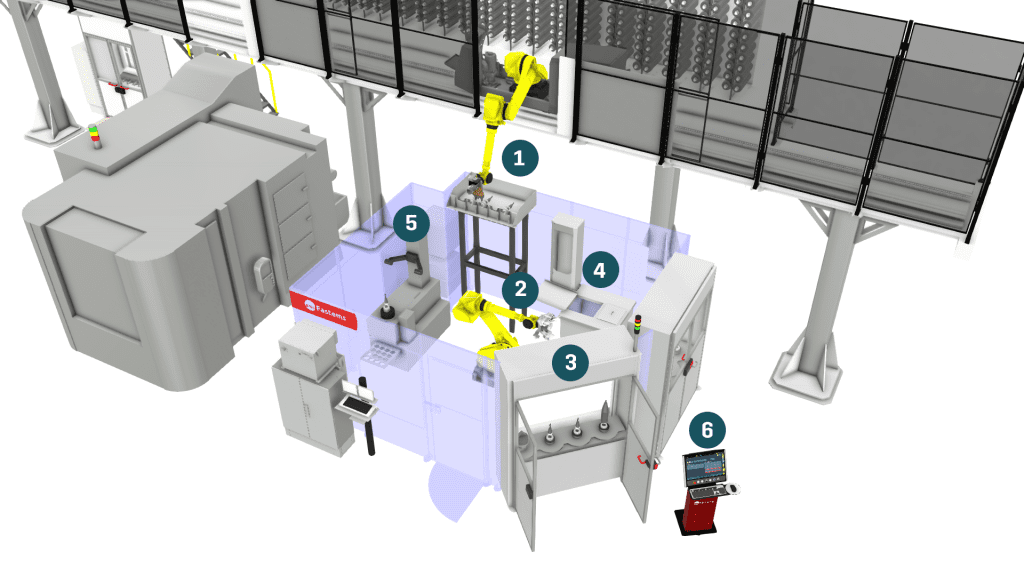

How does TSC work?

- Fastems tool automation automatically brings worn out tools to reworking.

- The robot cell moves tools through the reworking process, returning the reworked ones back to tool automation at the end.

- The only thing the operator needs to take care of is to changing inserts in an ergonomic tool loading station which holds up to four tools at once.

- Automatic tool washing and drying.

- Automatic tool presetting.

- MMS plans and schedules the tool reworking order based on the coming production needs.

Machine tool utilization above 95% + efficient labor usage

With short tool reworking times and an intelligent reworking scheduling, machine shops can achieve machine tool utilization of even above 95% . The biggest benefits of the Tool Service Cell however are gained by the operators: tool reworking is now something you can plan in advance and do all in one go without interruptions. This improves job flexibility and allows for longer unmanned periods. In addition, a tool loading station with spinning tool positions allows changing the inserts for up to four tools at once, removing heavy and repeating lifts, and greatly reducing safety risks related to sharp tools. You can read more about TSC here.

In these four posts we have covered all the four levels of the best cutting tool management practices. Keep in mind that it depends on the machine shop when it comes to the level one should aim for to achieve the best return on cutting tool related investments. To give you an idea, over 90% of the companies I have worked with are on at least level 1. At this level, MMS knows up to 96 hours in advance what tools will be needed in which machine and when. Learn more about cutting tool management and all the four levels here.

You are also welcome to join our virtual seminar Productivity Beyond Machine Tending on 4th November 2020. Cutting tool management will be one of the key topics!

Register for our virtual seminar