FMS ONE –

Flexible Manufacturing System ONE

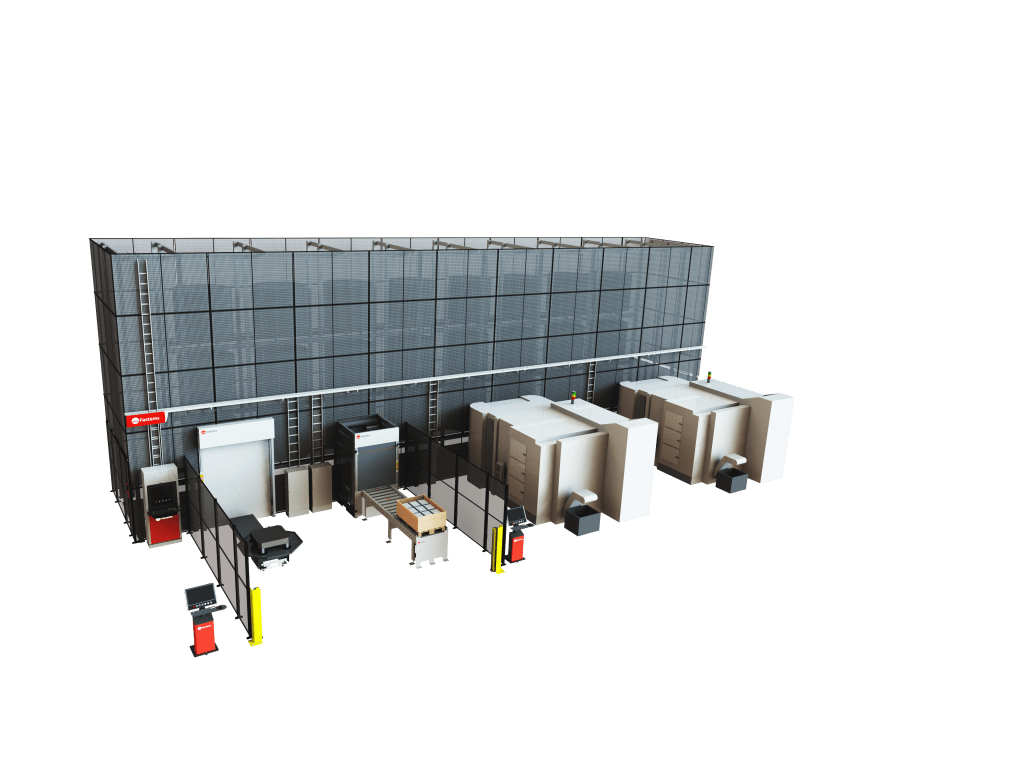

What is FMS ONE?

The Best Practices of Flexible Manufacturing

Want to integrate various machine tools while producing a large variety of workpieces? Do you need space saving storage for your pallets and materials?

FMS ONE is a standardized combination of the best features and practices of flexible manufacturing – created through decades of production development experience.

Furthermore, FMS ONE comes with the industry’s most advanced control software, MMS, enabling production scheduling and executing leading to full manufacturing transparency.

BrochureWhy FMS ONE?

All FMS best practices in ONE product

Intelligent production planning and scheduling software

Extended lights-out manufacturing

What you gain

FMS ONE Benefits:

- Excellent floor-space utilization

- Automation solution for every 3 to 5 axis machine tool

- Easy and straightforward extendability

- Extended lights-out manufacturing

- Great user ergonomics and intuitivity in operations

- High pallet transfers per hour-capacity

Optimization

Manufacturing Management Software

FMS ONE comes with industry’s finest production planning and execution software, MMS. Manufacturing Management Software is always one step ahead by automatically calculating the optimized production workflow and necessary resources, including tools, based on orders.

MMS adapts automatically to changes in the daily production schedule and displays information to maintain the production output.

Need support?

Services for FMS ONE

- 8760 support

- Service agreements

- Maintenance

- Spare parts

- Upgrades

- Relocations

- Training & Consultation

See FMS ONE in Action

Technical Data

|

Parameter |

LD-700 |

MDR-750 |

MDR-1100 |

MDR-1700 |

MD-1500 |

XMD-2500 |

XMD-3000 |

DSR-2000 |

| Load weight, incl. pallet | 700 | 750 | 1100 | 1800 | 1500 | 2500 | 3000 | 2000 |

| Nominal pallet size (mm) | 500×500 | 400×400 | 500×500 | 630×630 | 630×630 | 800×800 | 1000×1000 | 630×630 |

| Maximum load size

(X x Z x H mm) |

800x700x1000 | 660x660x1100 | 900x900x1250 | 1125x1125x1800 | 1000x1000x1250 | 1600x1400x1400 | 1800x1800x1800 | Custom |

| Load rotational diameter

(D mm) |

900 | 750 | 1000 | 1250 | 1100 | 1600 | 1800 | – |

| Material Management | – | – | – | – | Yes | Yes | Yes | – |

| Material pallet size | – | – | – | – | 800×1200 | 800×1200 | 800×1200 | – |

| Machining pallet storage | 2-4 levels | 2-4 levels | 2-4 levels | 2-4 levels | 2-4 levels | 2-4 levels | 2-4 levels | 2-4 levels |

| Loading station options | LSC | LSC, LSM | LSC, LSM | LCS, LSM | LSB,LSM | LSM | LSM | LSC |

"*" indicates required fields