Virtual seminar: Productivity Beyond Machine Tending

Online

Welcome to our virtual seminar

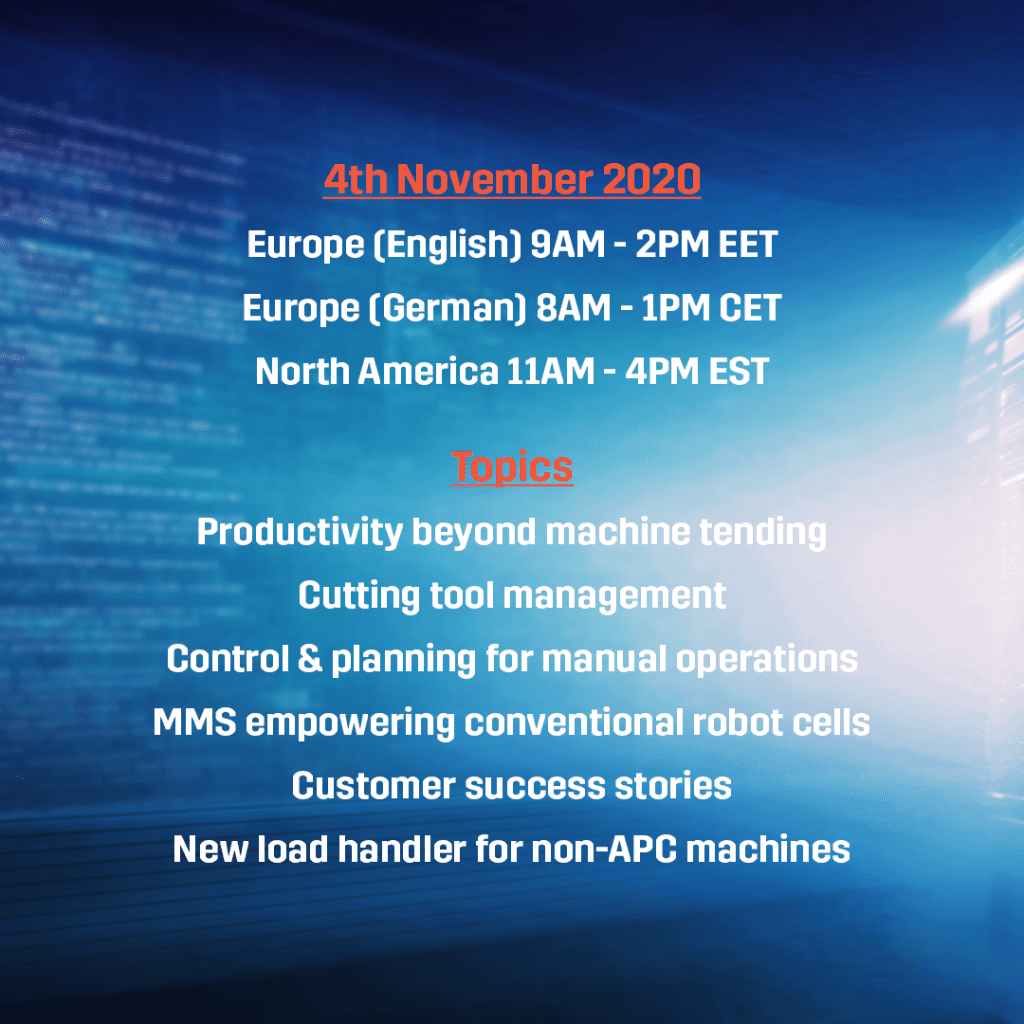

Manufacturers around the world have one thing in common: they want to be in control of their production, and deliver the right quality at the right time – all the time. Because of this, Fastems is hosting a virtual seminar “Productivity Beyond Machine Tending” on Wednesday November 4th, showcasing the latest developments in automation and surrounding technologies to all metal cutting manufacturers.

Our aim? To educate machine shops on how to improve their efficiency and quality step by step. Not only do we mean tending machines, but also evaluating the surrounding processes such as cutting tool management and other manual work phases to find the key bottlenecks that should be tackled first.

The virtual seminar will gather people in manufacturing industries across Europe and North America with educative webinars, video demonstrations and Q&A sessions on several productivity-related topics. A warm welcome on behalf of everyone at Fastems!

Register now!Updating webinar list

Productivity Beyond Machine Tending

Mikko Nyman, Fastems CEO

The word ‘automation’ is often understood as machine tending, that is, replacing a person with a robot. But manufacturing involves so much more than just the machine tools and the operators. How to manage the material and information flows in production and achieve order-based-manufacturing, without having to compromise in unit costs, flexibility, capital tied in WIP or lead times?

Read more

Building the best cutting tool practices from the scratch

Sami Pohjolainen, Product Manager

Through increasing machining complexity and product variants, cutting tool management has become one of the biggest time thieves on the shop floor – either affecting the shop efficiency, or production quality. In our presentation we will showcase how to implement the best tool management practices in 4 steps.

Read more

MMS WCO - Planning and controlling stand alone and manual work phases

Janne Kivinen, Product Manager

Fastems Work Cell Operations (WCO) opens the door for automating production and resource planning of stand-alone machine tools and other manually operated workstations. With WCO, you get full transparency of the manufacturing process of a workpiece and you can manage the factory with just one software. In this webinar we present and demonstrate how WCO works.

Read more

TDM Shop Floor Management for the realization of 8760 hour production

Volker Schwegler, Team Leader, TDM Systems GmbH

This webinar presents TDM Shop Floor Manager as the solution, and the integration between TDM and Fastems MMS for an optimal tool cycle to minimize data creation, maintenance and machine tool downtimes.

Read more

FMS for no-APC machines – customer success stories and the latest developments

Ilkka Saarimaa, Product Manager

Pursuing flexible manufacturing with 5 axis milling machines typically means automation solutions without pallet changers. Because combining manufacturing operations and moving from 4 to 5 axis is becoming more and more common, we want to present two customer success cases of “no-APC” automation. In addition, we want to launch our latest features for no-APC machines.

Read more

Benefits of Fastems MMS controlled robot cells over fixed cycle ones

Teemu Ahonen, Product Manager

What makes Fastems robot cells different? We explain how the MMS control empowers the robot cell to be flexible for more than just robotic loading. We will present our MMS and RoboCell ONE and demonstrate how the MMS automatic fine scheduling works in dynamic situations, how easy it is to introduce new parts into production, and how the system helps prepare for the upcoming.

Read more